Categories

Corner and Cove Moulding

What is corner moulding and cove moulding

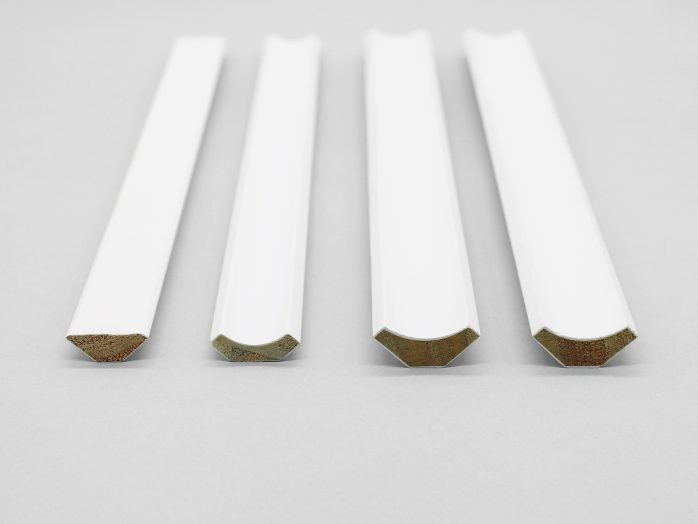

Corner moulding is a decorative moulding used to cover the corners of walls or to add a finishing touch to cabinets, furniture, or other woodworking projects. It is typically installed at the junction where two walls meet, creating a smooth and visually appealing transition. The cove moulding is one kind of corner moulding and due to is small size, so it is ideal when you need the moulding to cover the gap on your corner. Corner moulding comes in various shapes and sizes, allowing for different styles and aesthetics. It can be made of different kinds of raw materials, such as the MDF and various wood species.

why chooose us

1

Developing product system

We offer product development services and we are able to design and build the exact molding product you want. Our products are drawn in CAD format, and the production process strictly follows the confirmed CAD files to ensure that the products meet your required specifications, technical requirements and quality standards.

2

Strictly selected suppliers

When we select our manufacturing partners, we follow strict standards to ensure that they are all reputable institutions to achieve long-term continuous supply.After many years of cooperation, we have the trustworth and reliable suppliers, which also allows our customers to be assured of reliable, high-quality products.

3

Quality control system

Our commitment to providing high-quality products comes from our strict implementation of the quality control system. Whether it is the selection of raw materials, product quality control during the production process or packaging management , we strictly implement quality standards to ensure Ensure the final product meets your requirements and our strict standards.

4

Shipping management

We ship products to various countries around the world by sea. Our cooperative agents will help us select shipping companies with reasonable freight, fast and safe route to ensure that every order can be delivered safely and on time. We can accept various shipping terms, whether the shipping is arranges by us or client, or door-to-door delivery is needed.

An evolving supplier

Our company has a very open and inclusive culture, so our product system is getting richer and richer. Because we are willing to listen to the needs of customers from different countries and do our best to supply them satisfactory products. Although there will be difficulties in the process of developing new products, we will not stop because only continuous updates and the introduction of new elements can ensure the long-term development of the company.

The product details

Perfect milling Craftsmanship

The products are all milled with precise machines, so every side of the mdf corner trim and timber corner trim are all processed very well, even the curved surface is milled very smoothly and with precise angles.

Variety of raw materials

We have a variety of raw materials to choose from, whether you need the affordable MDF product or value-added wood products, such as oak corner moulding, pine corner trim,or other hardwood corner molding.

Improved primed surface

Our white primer corner trim adopts an improved primer production process. The thickness of the primer coating is only 0.18-0.2mm, which effectively solves the cracking problem of primer and also has good paint adsorption.

How to install the moulding product

01

Clean the installation area

Before installing moulding products, you need to clean the area to be installed, such as ensuring that the wall is clean and flat, and that there are no debris in the corner, so that the molding can fit tightly on the wall.

02

Measure and cut the moulding

Before installing the moulding product, you need to measure the required length of the moulding in advance, and then cutting the moulding with the saw machine, the miter saw is also needed to cut angles.

03

Installing the moulding products

Moulding can be installed with nails or adhesive. You can choose the installation method according to the desired installation surface effect. After installation, the adhesive is needed to the gaps.

04

Painting the moulding surface

Our white primed moulding surface is ready to paint, such as the white oak cove molding, you can paint the moulding surface with different color to match your home decoration style.

How to customize the product

Confirm required moulding specifications

We need to confirm the size and raw material of the product with the customer. We need to know the MDF corner molding or wood corner trims are needed, such as 2 inch wood corner trim. The surface effect must also be confirmed. White primed wood corner trim and white MDF corner or not-primed surface.

Make the CAD drawing

According to the product shape and product style provided by the customer, or the customer provides reference samples, we can draw CAD drawings based on this information. This is best if you already have CAD drawing.

Arrange the production

When the CAD drawing is confirmed and the order information such as order quantity and price are all confirmed, we will arrange the order production according to the confirmed CAD drawing. We can also arrange the order transportation.

Our raw materials

The MDF board

Our MDF inside corner moulding and MDF cove moulding are all made of MDF board produced by ourselves. The density is 580kg/m3, that is lower than other Chinese suppliers and the anti-bending ability is high, it will not break with the length of 16ft and 5.4.

The wood board

Our wood boards come from China and other countries. They all come from areas that strictly follow the principles of environmental protection, and the quality is very good. Therefore, our wood cove molding and wood corner molding are not only durable, but also environmentally friendly.

The primer material

Our primed coating are the gesso and water base primer. They are all branded products with good quality and stable performance, and optimized our formula to ensure the white primed effect on the moulding surface is stable and not easy to crack.

How to instore the moulding product

Keep the storage area dry

Because the raw materials of molding products are absorbent, it is very important to keep the storage environment dry. If the environment is humid, it will easily cause molding products to deform and become moldy.

Keep away from fire sources

Because moulding is a flammable product, so the storage environment must be kept away from fire sources. The warehouse staff must also pay attention and prohibit to bring fire sources into the warehouseprohibited to bring fire sources into the warehouse.

No direct sunlight

Do not let direct sunlight shine on the surface of the molding product, because direct sunlight will cause the white primed surface to fade, the color will be uneven, and the primer coating will crack and fall off.

Services we can provide

Customized product service

We can customize the moulding size, shape and surface effect according to the customer’s requirements to ensure that the product can meet the customer’s decoration needs.

Various quotation services

We can provide many different quotations, such as EXW, FOB, CIF, DDP or DDU. Providing a variety of prices can better facilitate customers’ cost accounting and price comparison.

Product quality assurance

The quality of our products can be guaranteed. If there is any loss caused by quality after sales, we will bear the loss and ensure the interests of our customers.

Product packaging method

- Regular bulk packaging: We use PVC film to package the products into small packages, then place 3-4 packages of small packages on plywood pallets and fix them with packing tape.

- Customized packaging: The product is packaged into small packages with PVC film printed with the customer’s logo. Each piece of moulding can be stick with the customer’s customized sticker and stamp.

- Individually packaged: Each product is individually packaged with PVC shrink wrap and labeled with a customer-customized product label. This product is usually sold in supermarkets.