Description

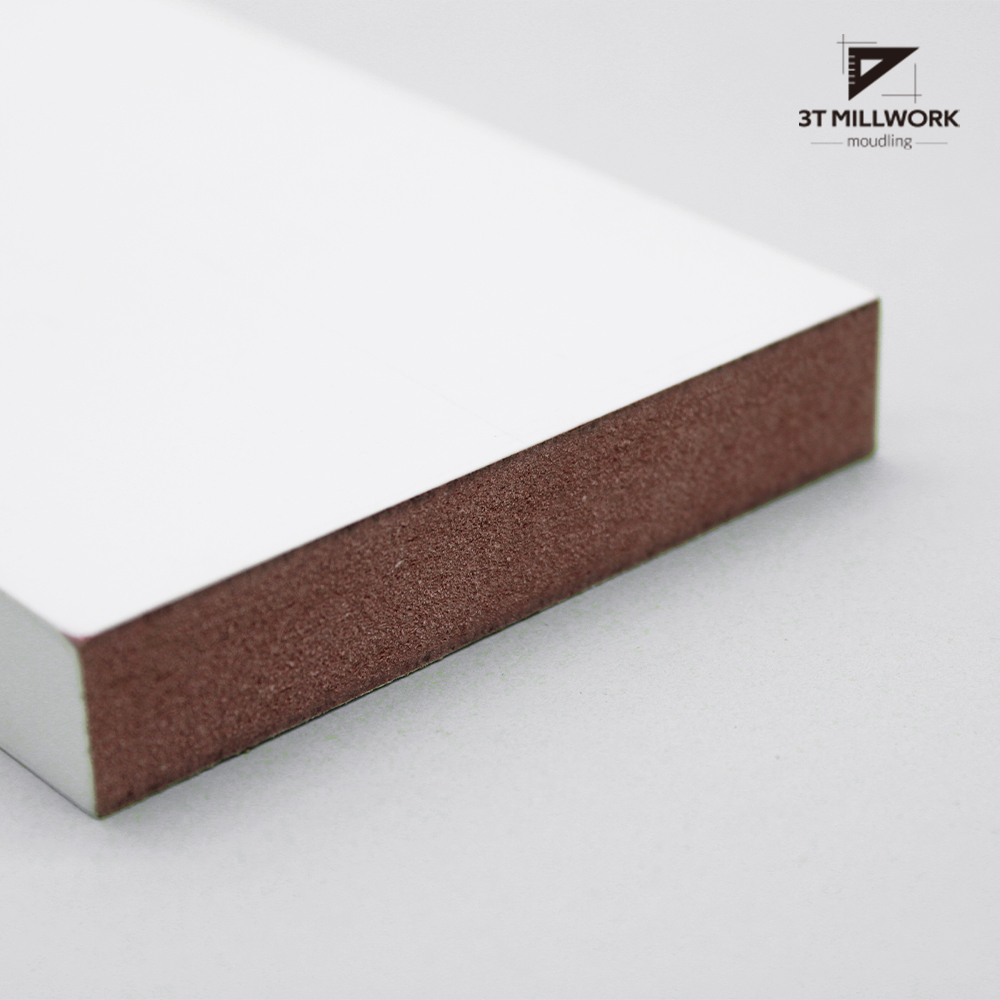

What is thick white baseboards

Thick white baseboards is a product which made with thick material and special machines, the more thick material, the more strict standard we have to matching. We supply extra thick baseboard for our customers in the market, 1 inch thick baseboard trim or more than 1 thick moulding are easy for getting from us. The maximum thickness of the moulding which we can made for you is 2-3/4 inch, this thick materials is not a product that you can get from any factories.

We are factory

A factory especially a very professional factory whose charging the production of nucasa mouldings from the beginning to the finished, is very important for the quality control and guarantee the performance during using. Most of the factory only do several production processes and other production processes are made by other factory, we are the one factory do the moulding from the beginning to the end.

Quick delivery

The delivery time is very quick since we do have big production capacity, the wood moulding can supply for our customers for 100 containers per month, 300 containers of MDF moulding, wall panel for 100 containers per month for our customers, so you can get the products in a very quick time and we have stocks of the materials for support the quick delivery.

Good service

The service is super in our factory during production of the moulding even for the special material like teak millwork and cedar base moulding, the shipment and package for the moulding, the shipment and after sales service for you when the moulding arrive your warehouse, during selling and installation, we all give more support for you.

Why Choose us

We can do any materials

We are factory and we can do any raw material different types of baseboard molding, there is no limited during the production of the moulding which related with the materials, but for some special wood, the request for the moulding production is needed, you need to talk with us in advance for the price and the request of the moulding.

No limited of sizes

The sizes of moulding do not have limited which are depend on your needs, or easy your installing baseboards and trim during working, the width can be customized with any also, so get different sizes of 3 baseboard molding and 4 baseboard moulding or any other special mouldings from us is available, price also very reasonable for these different requested of mouldings.

No limited for treatment

Some of our customers prefer to buy semi finished moulding from us cause all of the installing baseboard molding need a second coating, but few of our customers want to buy finished moulding which can allow them installation directly in their places, we do have different matched machines including package and surface coating in our factory to give the best support for you.

What about the treatment of surface coating

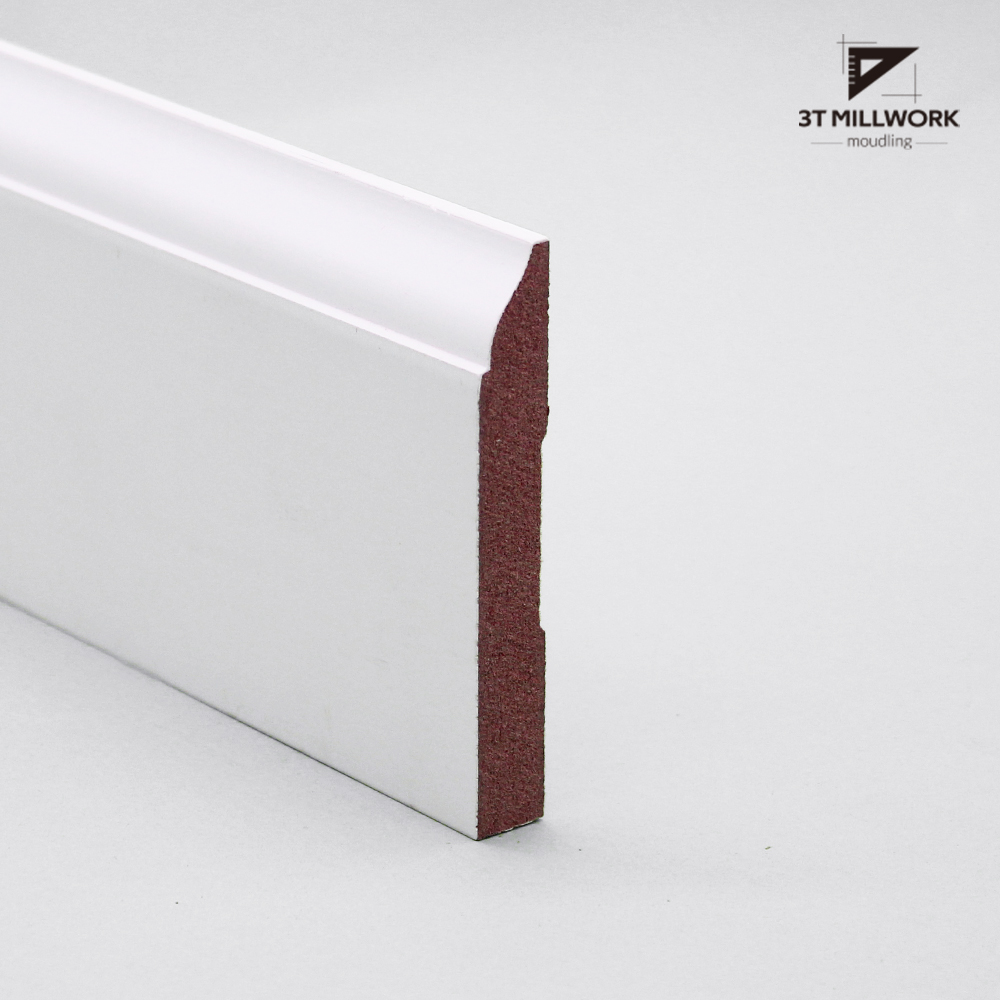

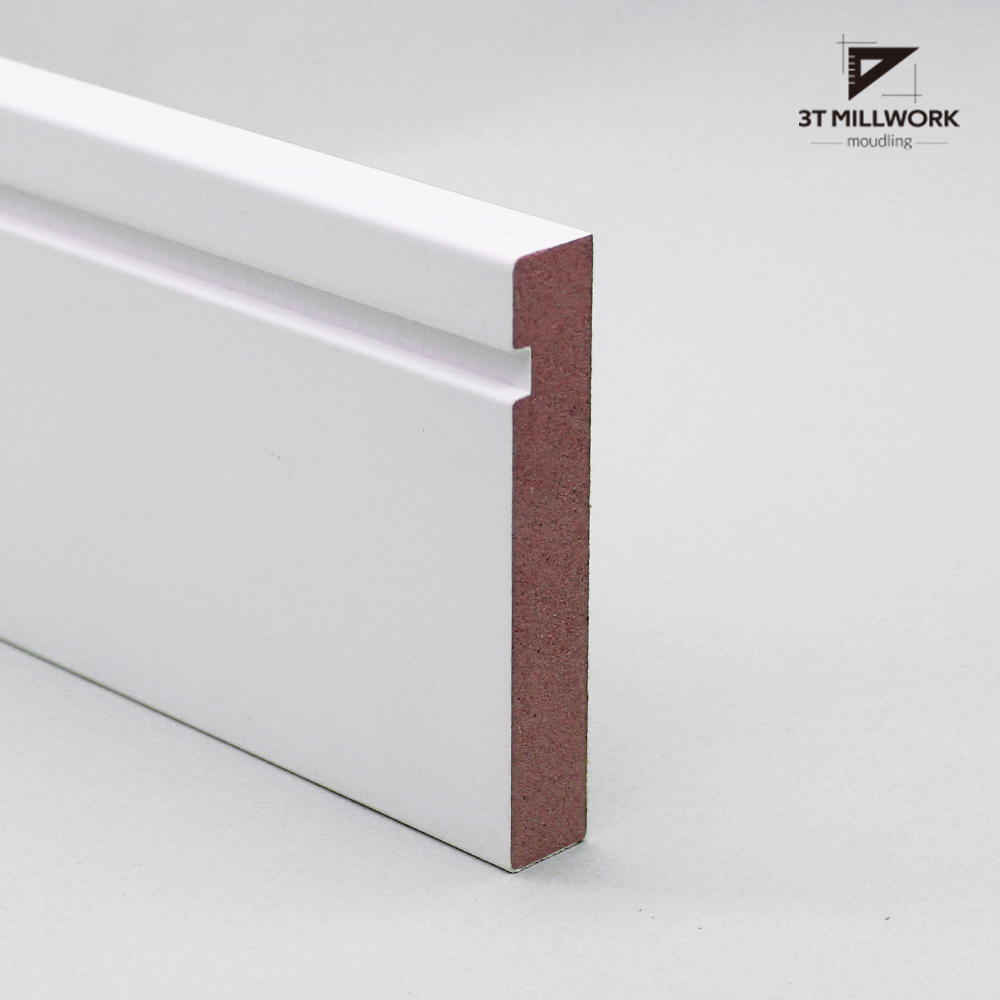

White primed

The most popular moulding no matter 3 inch baseboard trim or 8 inch baseboard molding are made with primed with base paint, this is a kind of products which is not finished product, you have to do surface coating with different colors painting in your places since they need installation in their places.

Lamination

Lamination moulding do have different method, wood veneer, paper and Plastic are all can be the material which do on the surface of the moulding, these kinds of moulding do not have primed coating before lamination, the raw board can be lamination on the surface directly without any base treatment on board, this kind of moulding can be used directly.

Painting

The painting of trimming baseboard molding can be chosen with different in our factory, clear paint normally used for the solid wood, the wood do have very high grade since you can see the material through the paint directly, the painting can be done on the surface of the white primed moulding surface also.

Which is the most popular material for moulding

Pine wood

Pine wood is not come from our local place, it is belong to a kind of softwood but it is super than any other softwood during production, we buy the raw log from New Zealand since the log do have bigger size and the price is cheaper, we cut them into pieces and make them into board with different thickness, than make the board into different thick and thin baseboard trim.

MDF

MDF is another material which is more stable than wood, this material do have more special feature since the price is more cheaper and make them can suit for all different environment, fire resistant and water resistant tall baseboard and base shoe which made by MDF are common now in the market, we are the board producing factory and can do the highest grade board for moulding production.

How to customize thick white baseboards

1

The width

The with of the moulding do have limited during production for the moulding which do have design on the surface, the most important is the four sided moulder machine do have limited during production, 3 baseboard trim or 8 baseboard moulding are the common sizes during production but the size which with designs will not more than 10 inch.

2

The thickness

Most of the moulding do have common thickness which more than 1 inch, and more than 1 inch thick baseboard molding cost is high in our factory, but the thickness which more than 1-7/8 inch do have request of MOQ when you put the order from us, the half container is needed for the order, means you have to put order with at least 3 pallets for that thickness moulding.

3

Materials

The materials for the production of kitchen baseboard molding can choose different from us, MDF and pine are more popular in our factory which you can buy in a quick time, but for oak, walnut, poplar or any other types of materials, the delivery time and the quantity you buy from us do have limited, the grade of them do have different also.

Compare with common moulding

- Longer delivery time: The thick baseboards with rounded corners come from thick material, the more thick moulding need more thick wood board during production, the thick board need more time splicing of wood, the MDF need to glue different board together for extra thick material like 2.5inch, so the delivery time will be a little longer compare with common moulding.

- High standard: The standard of thick molding baseboard with rounded corners are more strictly during production compare with common moulding, since the connection layer is easy broken or crack especially when you use nailing on it, so we have to make different pieces board with same Moisture content, density and make them much flat after put them together.

- Heavy weight: The weight of thick mold resistant baseboard normally do have bigger width during the production, the weight of the moulding definitely heavy than common moulding which made wood and MDF material, so you have to pay more attention during transportation and using, more then one person for 16 foot moulding for installation also.

How to installation our thick white baseboards

Glue

The glue installation is the only one kind of method for both thick and thin moulding, size and length will not infect the installation method with glue or nail, the special glue for installation 4 in baseboard moulding or 8 inch baseboard moulding are all available, you can get the glue for the installation easily in the market.

Nail

Nailing baseboard molding is another installation method for different sizes of moulding, the nail is very smaller and the smaller hole will be left on the surface of the moulding, so this kind of installation method suitable for semi finished moulding which need second painting after installation, the glue method suit for more thick moulding since the nail do have standard size especially for 1 by 6 baseboard.

Mixing

You can mixing the two method with glue or nail during installation since the different situation during installation, to make sure the fluted baseboard can attaching to the wall more tightly, but you have to pay more attention during installation especially for the moulding which is finished, different types of moulding suitable with different installation method.