Description

What is pre primed baseboard

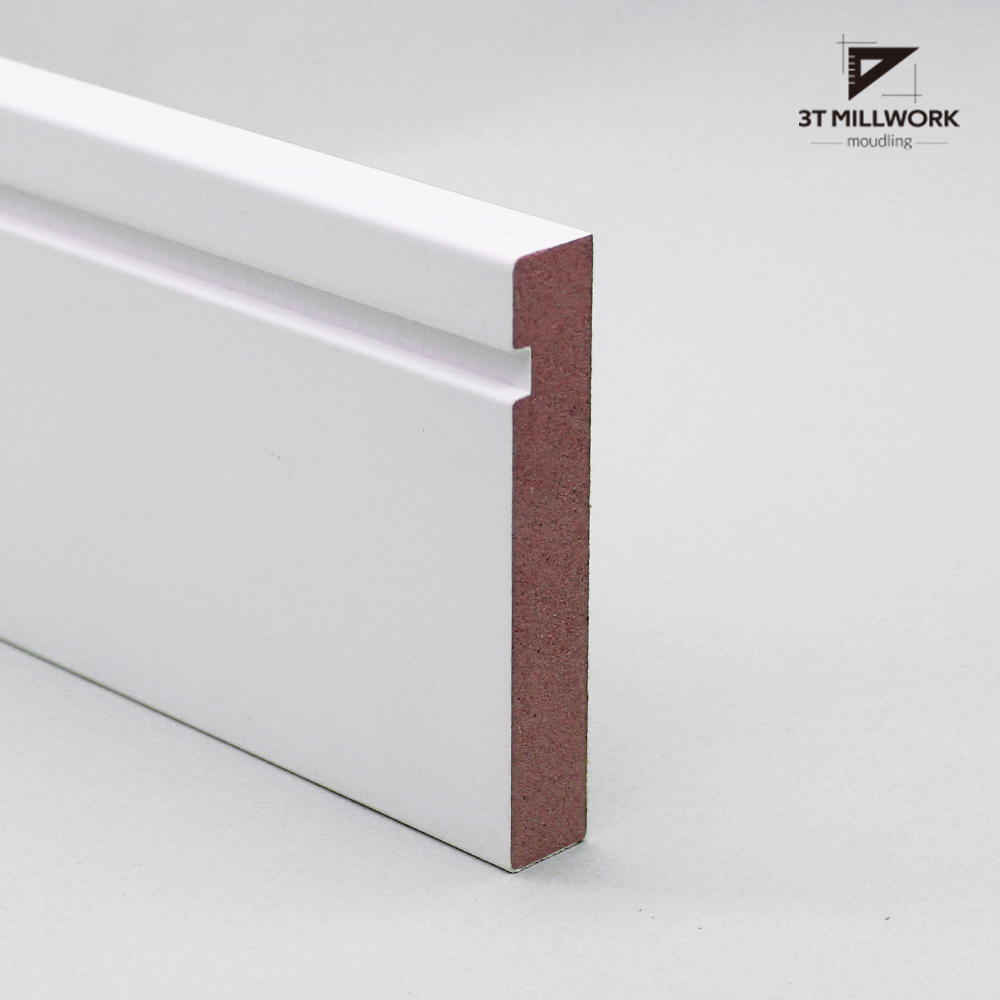

Pre primed baseboard is necessary when you want to decorate your room. It is used to the place where walls meet floors. It can not only protect your walls but also make the room look more beautiful. Our moulding has the smooth surface ,clean and regular forming and cutting process. when you touch it, you can feel the surface is very smooth and polished very flat. Good quality baseboards moulding can complement your casing well and create a smooth transition from the wall to the floor.

Various style

Different shim baseboard trim shape will make you room have different decoration style, we have hundreds of baseboard moulding profile for you to choose. Or you have your own design , tell us and we will make your idea become to the reality.

Good quality

Raw material is also important to the clamshell baseboard molding, we have a stable supplier of raw materials, and the quality has also undergone multiple inspections, so we can guarantee our moulding quality.

Easy installation

Of course, this traditional farmhouse baseboards is easy to carry and install, the density is low, but the strength is strong. Our baseboard moulding is primed, so it is ready to paint, you can paint it with the color that you need.

Decorative

If you install the baseboard, you will have a sturdy decorative feel when you live in the house. Home is a place that provides a sense of security, so choosing a baseboard trim industrial baseboard trim is a must.

Why Choose us

Professional experiences

We have produced the basement baseboard trim product for many years and have access to hundreds of different molding profiles, so you do not need to worry about our production capacity.The customized moulding profiles are ok for us and our experienced colleagues can give some suggestions to optimize product performance.

Quality promised

Our baseboard trim is made from the high quality material and the surface treatment is clean and smooth, the product quality will not let you down. We have the free samples of double baseboard molding that can be sent for you to check the quality, so if you have moulding inquiry or need the free samples, welcome to visit or contact us.

Large output

The output of the stacking baseboard trim is important, especially for pre primed baseboard production, the quantity we can supply is more than 300 containers MDF moulding, more than 100 container wood moulding that we can supply you, you can get any quantity of sticky baseboard trim from us.

How to use our pre primed baseboard

Installation

Nailing or gluing baseboard trim are the common method for using our moulding, you can take the moulding personally with one person, they are made with ultra light material like wood and light MDF board, easy your transportation and easy your installation work.

Replacement

They can be used in your room decoration for your new house, they can be used for replacing baseboards and trim in your old house, the moulding can be tear down easily as well as installation or replacing baseboard molding, give the best support for you and your work.

Details of pre primed baseboard

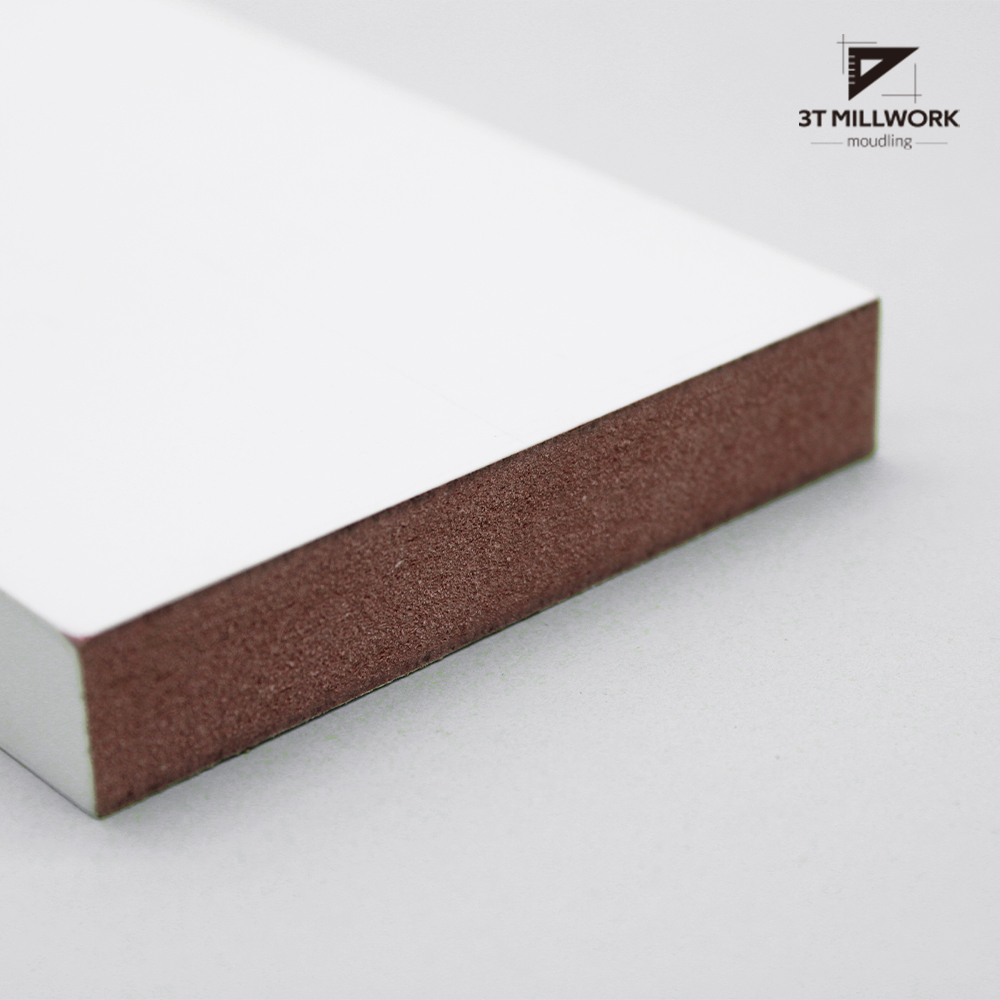

Approved surface quality

The good quality surface is very attractive. When you install the antique baseboard trim to your wall, it will make your wall base clean and smooth. Our moulding surface is with qualified quality, whether you need the white primed surface, or keep the wood natural color.All of the surface will be with good treatment, smooth and neat is our standard.

Precise milling finish

The built up baseboard trim is milled by the automatic and high precision machines, the machine can mill the moulding according to the confirmed drawings. It is total same as the drawings, even if it is a very detailed profiles and with many unconventional lines, we can ensure that every where can fully meet the customer’s needs.

Choose the prefer raw material

We have many different kinds of wood species and MDF for the baseboard moulding product. Different ogee baseboard have their own feature, the unique natural wood color and wood grain are important, they can add different decorative effect ot your room. Of course, all of our raw materials are with good quality and they can make sure the long service life of the product.

What about the profiles you can supply us

Moulding

Moulding is the most common product in our factory which do have finished and semi finished styles for your choose, there is no difference for us for different uses of profiles during production, so you can get window frame, wall panel, decoration moulding and baseboard and crown moulding both, we called them mouldings in our factory, for narrow baseboard trim or other profiles.

Door jamb

Door jamb is a special product during the moulding of ours, the unique reason is the standard design and the short size, sometimes we need to cut the head with 45°cutting and holes with hinges, they do not have any difference during the production as well as ranch baseboard molding, so you do not need to worry about anything for cooperation with us.

Hand rail and column

Most of hand rail and column are made with red oak or white oak, which material is come from USA and the A grade is the most popular type we used for them, but you can get support for any other different wood species or MDF material during production, different sizes and designs of these products that you can get from us besides mid century baseboard trim.

Factors affecting price

Material

This chapter is written on the year of 2024, at this time the most expensive material is white oak and red oak, they are higher for 4-5 times than a common material which we are buying in the market, so the material is the base cost of a product no matter you want to produce it with 4 inch wood baseboard molding or 6 wood baseboard.

Packaging method

The method for package the molding is another high cost since the bigger size of the moulding, package the straight edge baseboard by film with printing, LVL pallet is a common method for bulk order, but package them with shorter size moulding with shrink, sometimes a wooden box is needed during shipment, the price will be higher.

Base cost

The base cost is low for the production of MDF material but the base cost is very different for wood material moulding, A class or B class or C class materials do have different cost and we need to move the barks and do finger joint and splicing the wood again, the cost of the production and the waste will be more for wood material to make the price higher of a straight baseboard trim or newport baseboard.

How is the loading method

Pallet pack

The ranch baseboard trim is packaged same with any other styles of moulding, the pallet need to be custom according the size of the product since the longer size of it, we made them by LVL material in order to make them easy exporting without any treatment again.

Longer size

The size of the ogee timber mouldings are longer to 16 foot to 18 foot, so they are more longer during the container loading, so we only can loading the container with 6 pallet, each pallet do have 7 smaller bundle with a small pack.

Need cooperation

The loading and unloading method with these longer size of moulding are not that easy, but not hard we think, a cooperation work during loading and unloading with two forklift is needed, no matter for barn wood baseboard or any other styles of moulding.