Categories

casing moulding

What is casing moulding

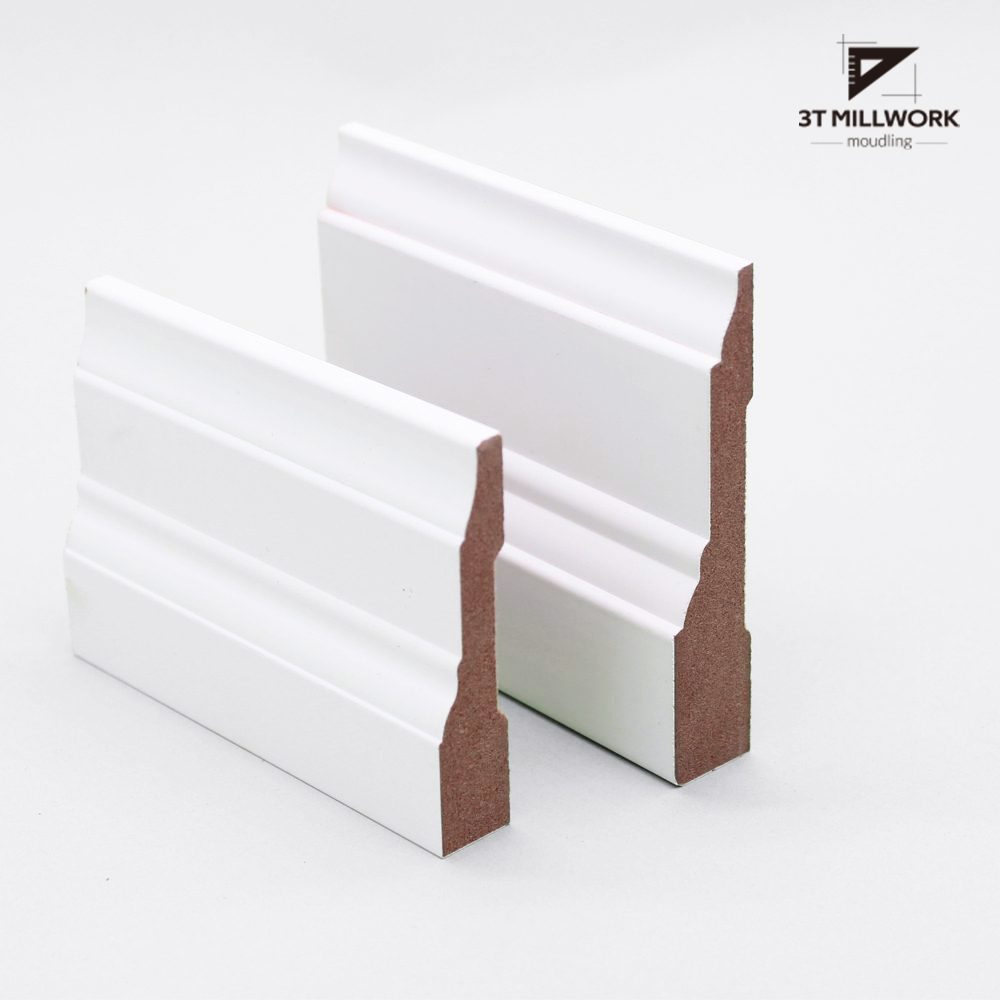

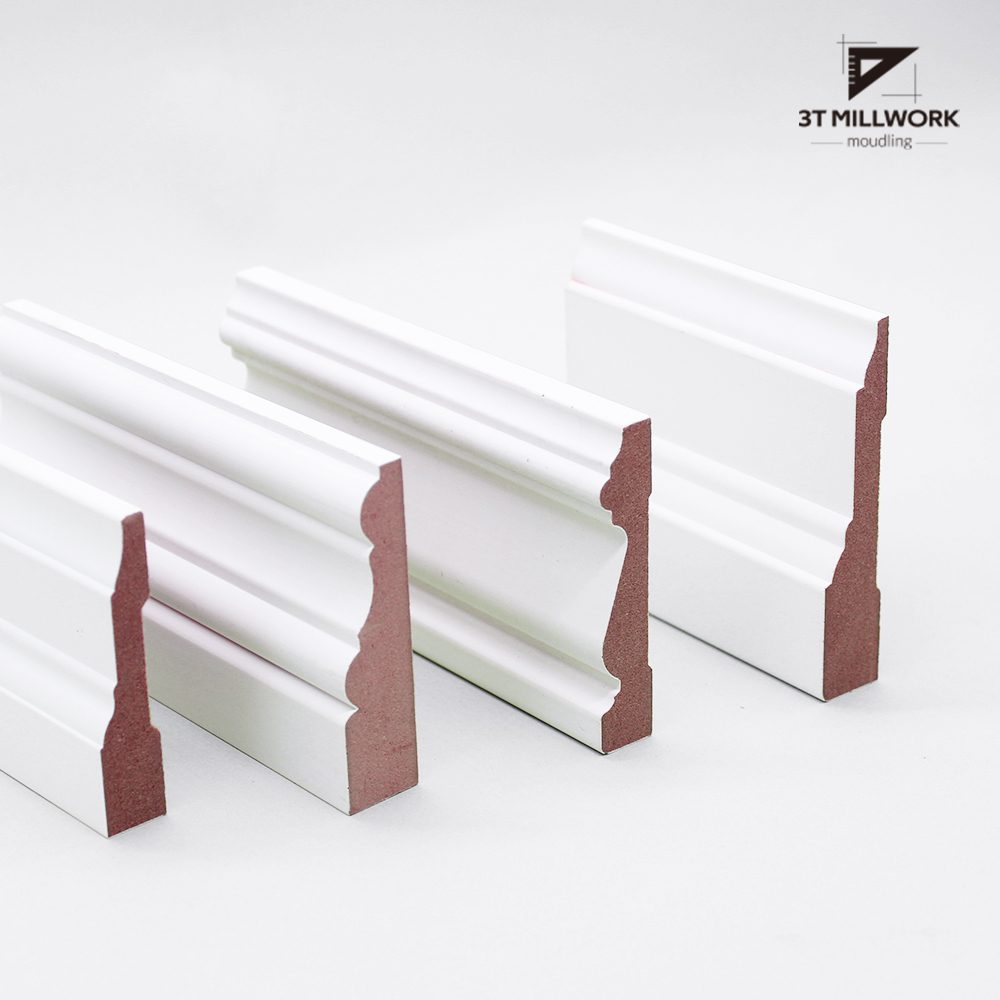

Casing moulding is one decorative moulding product that is installed around the door and window. With different moulding sizes and shape, there are different kinds moulding style used to match the window and door. The casing moulding has the aesthetic purpose to add the decorative elements, also has the functional purpose, used to cover the gap between the wall and the window or door frame to create a finial look and protect the edges of door and window. It can be made of different kinds of raw materials, the MDF and wood moulding are popular choices.

Why choose us

Experienced in the product

Our company has been engaged in the production and export of various kinds of moulding products for long time, so regardless of product issues or product import and export transportation issues, we have rich experience and can work with the customers to complete orders together.

Various existing production molds

We have cooperated with many customers from different countries and produced many different moulding profiles, so we have many ready-made moulding production molds with different size and styles, which can help customers save the production mold cost and save the time to make this mold.

Sufficient warehouse area

Our storage warehouse for the raw material and finished product are big enough, so we can prepare the raw material of popular moulding products in the warehouse, saving the time to prepare the raw materials. At the same time, we can store some inventory products for the clients, reducing their inventory pressure.

Strict quality control

We pay much attention to product quality, because only good quality can keep customers trusting us. Therefore, we have very strict quality control standard. From the raw materials, product production process to final product packaging and transportation, the quality is strictly controlled to ensure each pcs product is qualified.

The types of casing moulding

Different moulding styles

Different raw material

Professional moulding supplier

Our company has been engaged in the production and export of moulding products for more than 10 years, so we are very confident in our own professionalism. Not only do our design, R&D and QA colleagues have professional product knowledge and can optimize our products, they can also provide professional advice on product performance according to customer requirements. Each of our workers responsible for production is also very professional. They all have more than 5 years of experience in the production of moulding products, so very familiar with how to control product quality, which greatly reduces the rate of unqualified products.

Advantages of our casing moulding

1

Customized products

After receiving the customer’s specific requirements for different casing profiles, we will make the CAD drawing and arrange the production according to the drawing confirmed by the client. Precise CNC milling process ensures product accuracy. No matter what style or size you need, we can produce it for you.

2

High quality raw materials

Our raw materials are all with high quality, the MDF moulding density is 580kg/m3, high anti-bending ability. The pine casing are made of the New Zealand radiata pine and has options of knotty and non-knotty. They strictly follow the highest standards to control the size and quantity of pine knotty.

3

Various surface treatments

The moulding can be with different kinds of surface treatment. The white primed moulding surface is coated with the gesso and primer or the non-primed surface with raw material color,this is common used for the wood moulding. The laminated melamine surface or moisture-proof surface are all ok for us.

4

Fair product price

We are the factory price, so there are no other third-party fees included in our prices. You don’t need to worry that we will deliberately raise the price for you, because what we need is a long-term cooperative relationship and a win-win cooperation.

How to installation the casing moulding

Measure size

Cut the moulding

Fix moulding

Surface painting

What is the MOQ of the product

The full container order quantity is a good choice for us and the clients, because if your order quantity is more, the customs clearance fees, agency operating fees and shipping cost each ft of moulding will be lower. Furthermore, our production cost of the larger quantity will be cheaper than small quantity, so we do not suggest the LCL. The full container of one moulding profile is the best quantity, but if this order quantity is too large for you or as a trial order, you can mix 3-4 different kinds of moulding profiles in one 40ft container.

How about your delivery time

Our production capacity is approximately 200 × 40 ft container MDF moulding and 50 × 40 ft containers wood moulding per month. Such production capacity can meet the order needs of most customers, so we can guarantee on-time delivery. Usually our new orders take 15-20 days to ship, if it is a product from a previous order, it only takes 10-15 days to ship. Usually wood moulding production takes longer than MDF moulding.

Material for casing moulding

The raw materials of our casing moulding are all of high quality. Our commonly used raw materials are pine wood and MDF boards. The pine is radiata pine imported from New Zealand, which has stable performance and can maintain good performance for a long time. Our MDF board is independently developed and improved by us, so the MDF moulding density is 580kg/m3, which is a density that other Chinese factories cannot provide. Moreover, our MDF has very good anti-bending ability, not easy to break even with the length of 16ft and 5.4m.