Description

What is hardwood timber mouldings

The solid wood do have two different types, one is hardwood and the other is softwood, hardwood do have high density and more harder than softwood. Many customers do not know the softwood and hardwood, hardwood are two types in our normal use, one is mahogany and the other one is miscellaneous wood. Beech, elm, oak and so on are called miscellaneous wood, rosewood and wenge are called redwood. Hardwood timber mouldings is popular in the market, the most popular and the main material in the market is pine wood. Oak casing moulding is one kind of hardwood that you can buy from us, most of this kinds of raw materials are come from New Zealand, bigger logs with good density, can supply us a base good material for moulding making. We do have so many different machines, all of them are used for moulding making, no matter for finger joint, drying wood, cutting wood or moulding painting, we all can supply you very good products. To assist you in visualizing the final result, we provide a gallery of inspiration showcasing our moulding in various settings. This allows you to envision the different design possibilities and find inspiration for your own project. So if you have the requirement about the hardwood millwork product, you can tell us and we will meet your need.

1

Super nail holding ability

Hardwood is a super products when you use it for door jamb or any other profiles which will do hinges or locks, you can work with the nails on the hardwood for many times.

2

Easy to doing texture on the surface

The more complex texture can be done on the surface of the hardwood, like oak casing trim, redwood trim molding or cherry cabinet trim, the texture is stronger even the shapes are very sharp on the surface of the moulding.

3

More durable using

They are more durable using cause the high density of the knotty alder moulding not easy broken in using, you can fixed it easily and not easy broken, these features make them durable using.

4

Many luxury wood can chosen

Oak wood molding, red cedar trim molding, wood trim ornamental molding and cherry mouldings are all can choose from us, you also can get ogee wood moulding, sapele mouldings, mahogany casing trim, ovolo timber mouldings and scotia timber mouldings from us.

Strength of our company

Do have more production experience

We are factory that doing wood moulding production for more than 25 years, you do not need to worry about anything including quality control or new designs development, we are your trustful partner for buying moulding.

Professional technical workers guiding

We do have more technical workers whose familiar with the features of all kinds of wood, we will do the production according to the different nature of the wood, to make sure the quality of your moulding.

Support all kinds of wood material

You can choose different wood materials from us even they are hard to get and more special, oak fluted trim and unfinished cherry moulding are easy to get, but albergia odorifera moulding and Pterocarpus santalinus are all available for us.

Why Choose us

Sample available and free

To further facilitate your decision-making process, we offer samples of our hardwood timber mouldings products. You can request samples directly from our website, allowing you to assess the quality, texture, and finish firsthand before placing an order.

Good experience of cooperation

We believe in the importance of ensuring customer satisfaction and providing you with the confidence that our products will exceed your expectations. Once you have selected the desired wood moulding profiles, our streamlined ordering process ensures a seamless experience.

Easily ordering

You just tell us the type of the wood, style of the moulding or show a picture to us, you can get our quotation in 2 hours, you can get our shipping cost to your nearest port or warehouse, you can asked us to send the goods to your warehouse and send you the total cost.

Application of hardwood timber mouldings

Stair handrail

This is a bigger size and more complex design moulding in our factory, some of the files are much bigger with the square shape, we have to package them by individual and package them in a good situation for shipment.

Corner block

We use beech wood for the corner block making now in our factory, you can choose the other hardwood if you do have the request of the raw material, all of them are non knotty wood material.

Smaller moulding

The smaller moulding do have more strict request cause they are easy broken with longer size, so the cost will be more with softwood and the hardwood will be a super choice.

Any other high value frame

Cause the high value of the raw material, it is not suitable for you to use them make your low profit products, but for a high value decor or frames, you have to use more durable material to promise the quality.

Types of hardwood timber mouldings

Raw

The raw moulding is not easy to making for all of the factory, so you can hardly get a quota for your moulding with raw, the knotty will not be accepted on the surface of the moulding, and the smooth and the finger joint will be more super which will ready for clear painting.

Painting

Painting directly on the surface is available on the hardwood moulding, the surface need to be treated more smooth and make you can paint it with more uniform on the surface, you can use the face paint do the coating directly on the surface of the moulding.

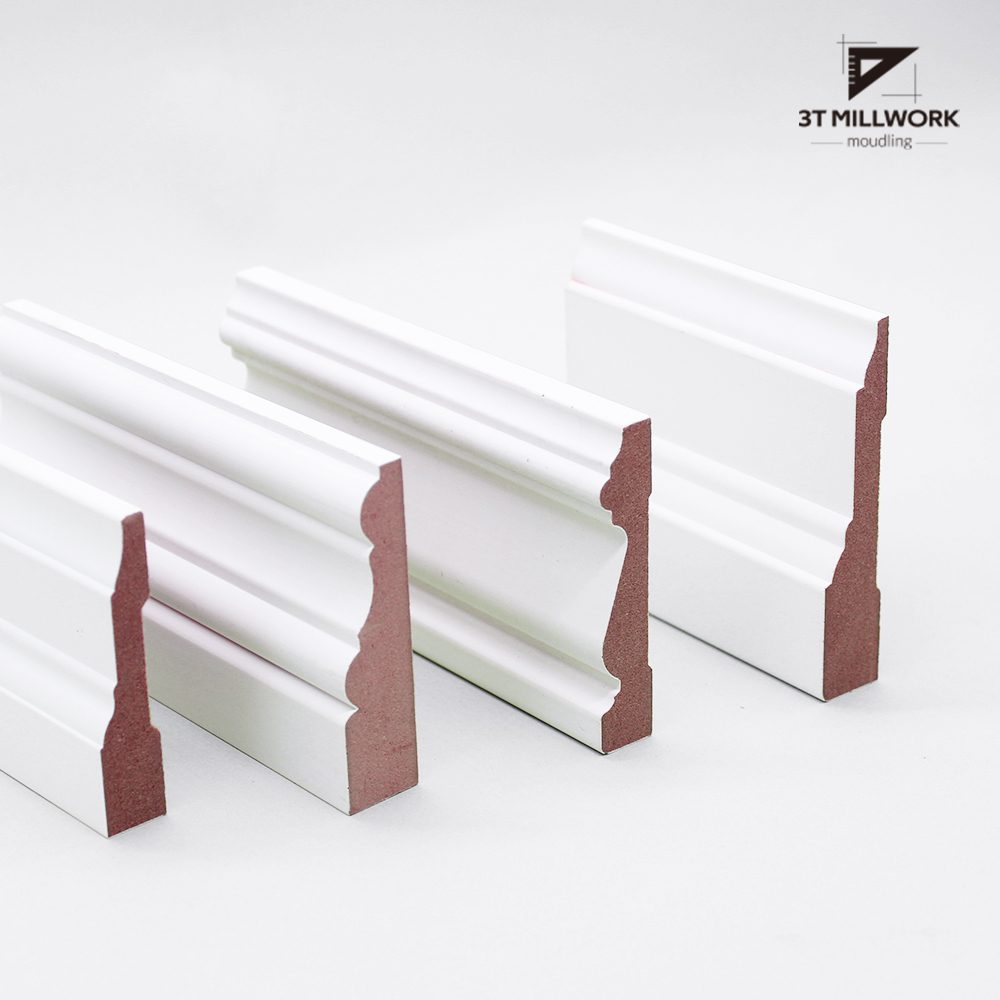

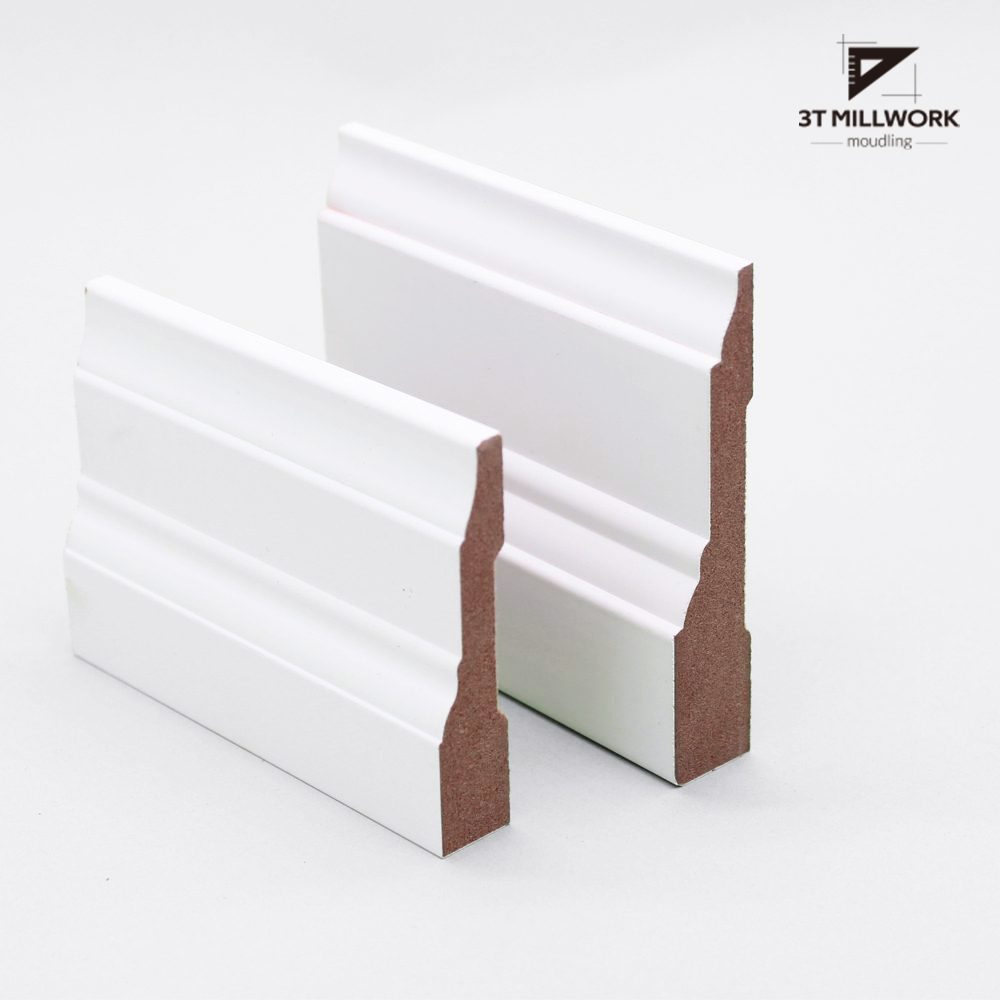

Primed

Primed is the common treatment on wood moulding which we are doing them now, you can choose this coating method and painting them in your own workshop or after installation them, we can supply you many treatment for these kinds of hardwood moulding especially for special wood.

Request when you buy hardwood timber mouldings

MOQ needed at least 20 CBM

Not like wood wall molding, most of the mouldings do have smaller size which used in different places, but for special materials which we are not usually used, you have to order more than 20 CBM for moulding producing since we do not have stocks for them and we will not do stocks for all kinds of raw materials.

Sample need confirmed for more complex design

Also not like frame moulding wall using, they only do have simple and regular design on the surface, the complex design need sample confirming by you and than we can begin our production, these complex design do have more curve or pattern on the surface.

We need confirm your drawings for special design

Though almost all of the mouldings are designed for wooden moulding on wall, but they still have different types which can matching your different styles in your house, the timber wall moulding can be more complex which only can be produced after getting your 3D designing of it.

How to package the hardwood timber mouldings

Individual package for bigger size product

Wall molding wood for decoration or wall reeded timber mouldings for panels are very different using and different sizes for producing, the construction is also very different from each other, they are not same products in our eyes, but no matter which types of the moulding you want to buy from us, the individual package can be done here in our factory. They can be Stair handrail, knotty alder casing or wall panel, all of them can do this package depend your request.

Film and foam protection in carton box

This method only for special wood with high value, you can paint them into finished products and you also can use special wood with high value also. We have to give a perfect package due to the high cost of the products, especially when you ship them in a long way, we have to do a wooden box to package them if you are not loading in the container. Shrink by film and protect by foam is necessary sometimes for special designs of the moulding, you can come to know more from us.

Boxes package with protection inside

Now we package the corner block with carton boxes, the size is smaller and the length is also much shorter than any other kinds of mouldings, so we have to do a carton boxes with 5 layers for package these smaller mouldings for you. They are now mostly loading in the container with any other mouldings together, so more safe shipment situation and do not need to chose more protection method for shipment.

Pallet package for normal size and length

Pallet package can be done with both longer size and also shorter size, the length of the pallet do not have limited for you, the longest size we are doing for our customers is around 5400mm for Australia market, it is not that longer which used for USA market. You can get more support for shipping method of package method, especially you want to sell your products online, a manual and barcode is needed for put on the package.