Description

What is mdf casing

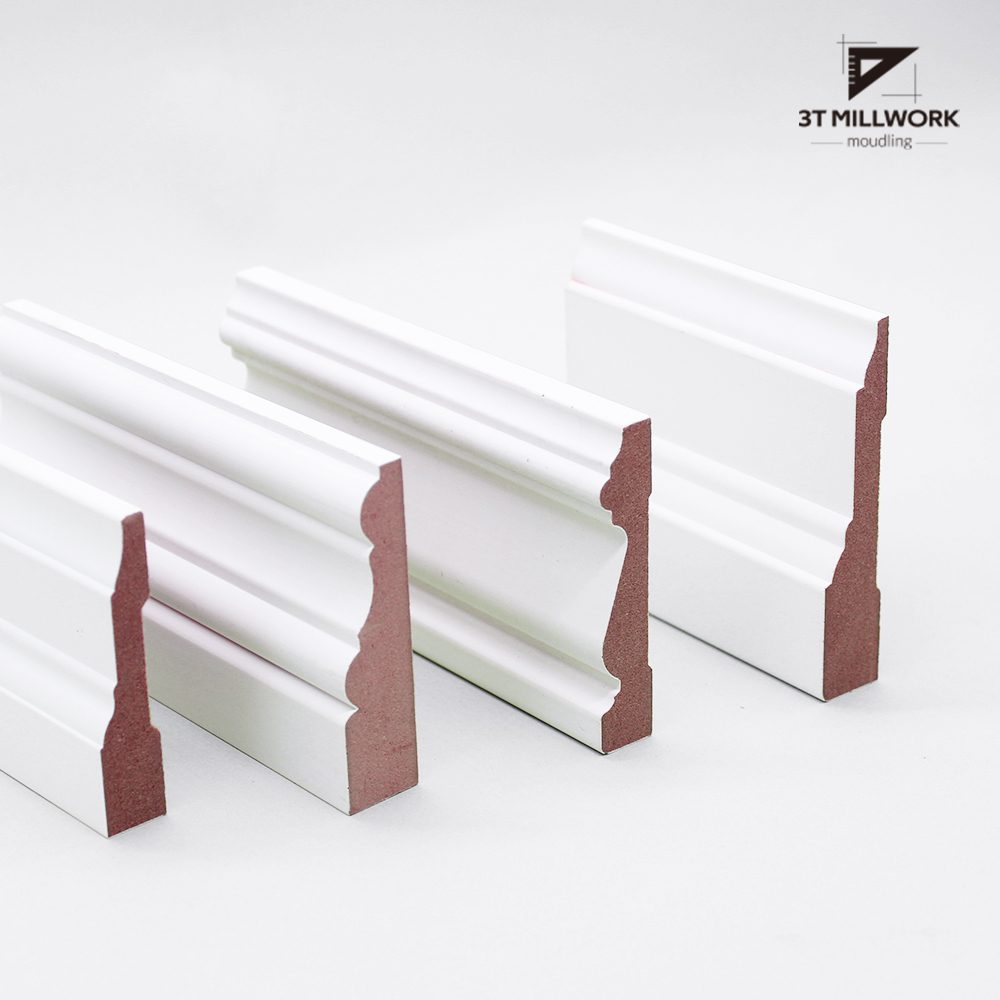

The mdf casing trim is a type of interior decorative trim that is made from medium-density fiberboard. These mdf casing profiles are designed to add decorative flair to doorways, windows, and other interior openings, also has the function to cover the gap between the wall to the interior openings . MDF casing is a popular choice for homeowners and builders alike, due to its versatility, durability, and affordable price. The MDF board is manufactured by compressing wood fibers and resin together under high pressure and temperature. This process creates a durable, smooth and consistent product that is resistant to warping, cracking, and splitting. Compared with the traditional wooden casing that may need sanding, filling, and painting to achieve a smooth finish, the mdf casing moulding comes pre-primed and ready for painting, saving time and reducing labor costs. We have various kinds of mdf colonial casing with different profiles and sizes, allowing the homeowners and builders to choose a product that fits the decor style of their other space. From simple and sleek designs to ornate and intricate details, the casing moulding can be customized to meet the design needs of any project.

Cheaper price

Besides, the mdf casing is significantly less expensive than traditional wooden moulding, making it an attractive option for homeowners and builders on a budget. In addition, MDF casing can be easily cut and shaped to fit any size opening, allowing for a precise fit and seamless finish.

Environmentally

As we all know, the MDF board is made from recycled wood fibers, reducing the amount of timber that needs to be harvested for construction purposes,so the MDF product is also a sustainable product. Overall, MDF casing is a versatile, durable, and affordable option for adding decorative flair to interior openings.

different designs

With its numerous design options, ease of installation, and sustainability, it is no wonder why MDF casing is becoming an increasingly popular choice for homeowners and builders alike. You also can get any samples from us for a quality checking, so come to us to request a sample and we can mail you as soon as possible.

Strength of our company

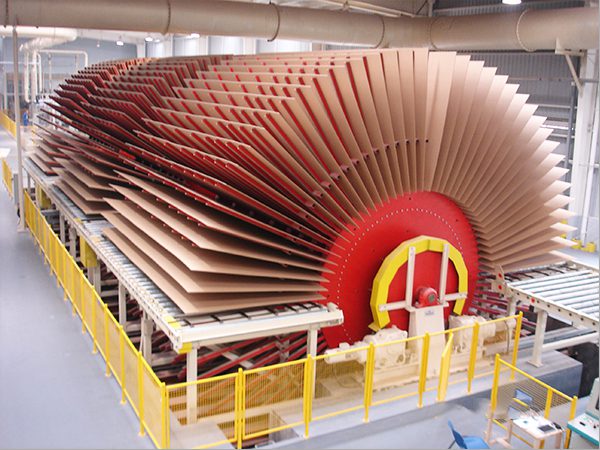

We produce the raw material

Strict standard for moulding board

More thickness materials

Why Choose us

High Quality

You have to control the quality from the raw material to the finished MDF casing, each production process and each material you will using, all need to be controlled in a high quality situation, you do not need have this worried if you choose us as your supplier. We have our own data for MDF material product in our production line and all of the material need to under strict checking, to make sure the finished moulding do have the highest quality for you.

Low density

Most of the time, the quality of the fiberboard is determined by the density of it, it means the heavier density of the board, the better quality you can get. But for a special type of the board which for moulding production, you have to make a type of board with lowest density but much stronger than high density one. Make you can loading more in one container and will not easy broken, the quantity of our MDF moulding can be load same with wood moulding.

Good price

Due to the raw material and finished moulding are both produced in our own factory, no more extra fees with transport and traders profit, we can control the base cost in a very good level, no matter can promise the quality for the MDF moulding but also can take all of the risk which related with the quality, you can hardly find one factory do have this confidence for both quality and price like us.

In time delivery

We never delay our customers delivery time to make sure they can get our goods in time, they can tell us the shipping time with their agent or they also can tell us the arrive time with out agent, we can handle the goods in a very stable shipping way and time for them. This is much important for a better arrangement for the planning of the production and buying, on time delivery is much important especially we are in such long different location.

Details of mdf casing

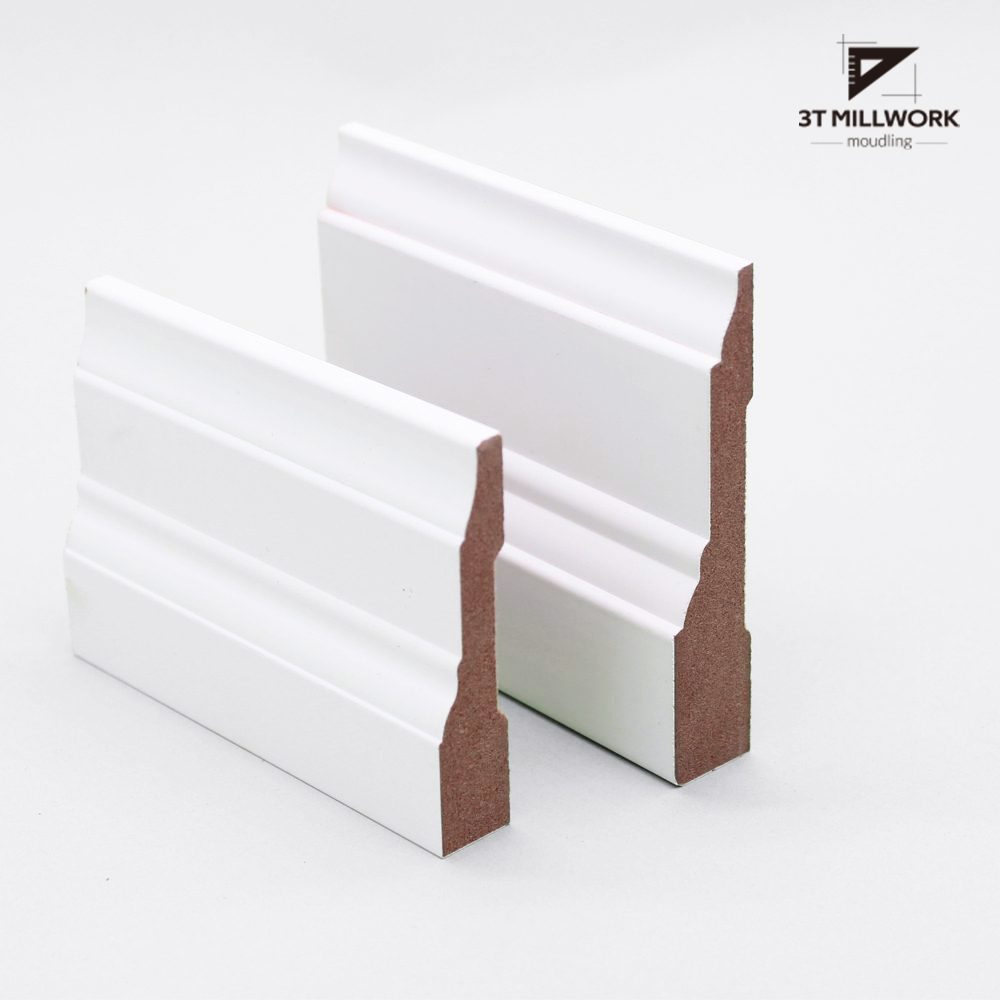

Smooth surface

The mdf fluted casing surface is much smaller compare with the wood material, so it is much easier to handle and produce them, the surface can be much smooth after we do thinner coating on the surface.

Thinner coating layer

As you know for the ovolo mdf architrave product, the thinner of the layer is, the better of the quality of the moulding, cause it is not easy to broken or fall off during using.

Good density and fiber

The fiber comes from the logs with pine or any other hardwood which removed barks, they do have good and longer fiber to make sure the quality of the board for the MDF moulding.

How to customize MDF moulding

01

Tell us the type of the material

It mean which grade of the glue you want, as you know we can do different grade which from E2 to F**** products, the more higher of the grade, the more expensive of the moulding. Though the most common grade for MDF moulding is Carb P2, we also can supply you different types for it.

02

Tell us the size you want

Size can be very different when producing MDF moulding, extra wide size or smaller size are all available in our factory. The smaller size do have high cost compare with the bigger one, so knowing the size firstly is necessary for the price calculating for us, to supply you correct cost for each type of the material.

03

Get our quotation

The quotation will be calculating after know all of your requested, the surface treatment method, the size and thickness of the moulding, quantity you want or any other requested you have, than the quotation will be supplied for you, the shipping cost will be send to your for compare along with the base cost of the moulding.

04

Sample supplied if needed

You can get our free sample for both MDF and Wood, they will be send to your in 3 days and you can check them if you want to check the samples before your bulk order, this is depend on the price approved for you, the sample is always necessary for supply you, you will have more confidence for both us and our moulding.

05

Choose the types for the trail order

Due to the designs of the MDF moulding do have more than 300, you have to choose the most common type in your market, this is necessary for a trail order with smaller order, you can give us your yearly production plan in the future, we can do the arrangement for you.

06

Payment and production

We can make the contract for you after you choose the type for the trail order, the production only can begin after we got your deposit, the production time will be negotiation with you before we sign the contract and we can guarantee the time for delivery, we always keep in touch with you and stay in one page with you for all things.

Application of MDF moulding

Window and door

Mdf door mouldings, mdf for window casing and mdf door trim all can choose our MDF material for production, the nail holding and the painting are all good compare with the wood material, but the price will be more cheaper.

Floor and celling

The smaller floor trim and shoe moulding are all ok, the crown moulding with beautiful design is also can made with our MDF material, the performance is super no matter you use glue and nail to installing them.

Chair and stair

These two different moulding do have thick thickness sometimes, but we also can supply you with your request as wood material, painting or veneer both available in our factory.

Any others

Much smaller moulding like corner block, quarter round moulding and T moulding all can be made with MDF material, the good density and the stronger feature make all kinds of the designs available.

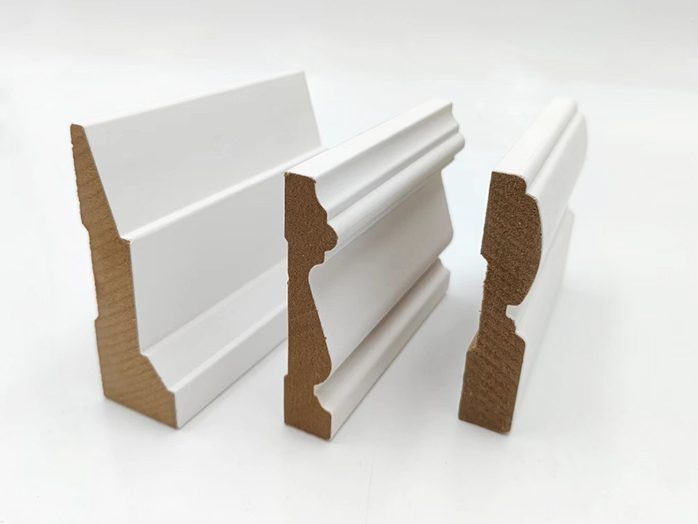

Types of mdf casing

Primed with Gesso

This is the popular moulding which we used and producing now, it is a kind of semi finished moulding, you have to paint it with the last coating with any color you want after you installing them.

Lamination with paper and vinyl

This is a type of finished products that you can do the treatment on the raw material directly, the production machine is much different from primed or painting, but colors do have many that can be chosen from.

Wood veneer lamination

This is also a type of finished products, but they can be made with wood veneer that make them looks like a wood material, all of them are nature color with super treatment.

How to maintain the mdf casing

Far away from water

As you know the MDF material will be expand after connection with water for a while, than the shape will be changed than, so we do not suggest you put it next to the water.

Safe placement

Moulding should be placed on shelves or packed in pallets to prevent products from deforming and breaking due to improper protection.

Far away from fire

The MDF moulding is made from wood, so it will be on fire if there is fire next to it, you have to keep the place without flames or it will be in danger.

Material introduction

- High Density board

We called the board with high density board with the density higher than 830kg/CBM for the thickness of the board with more than 12mm, it is a very heavy board and it will be fire resistance if the density much heavy like 1200kg/CBM. Usually used in kitchen and bathroom, but not for moulding. - Media density board

The density for the board which more than 12mm will be in 650-830kg/CBM, this is the material can be made for moulding but the length will be limited, it will be big risk for broken so when you make the length more than 14feet, you can use this kind of material for mdf wall moulding or door jamb with short size. - Light density board

The light density board is the density which low than 650kg/CBM for thick board, now we can do the density of the board with 580kg/CBM, the thickness of the board can be 12mm to 35mm, all of the density and feature is good in producing and using, we can guarantee the quality for you.