Description

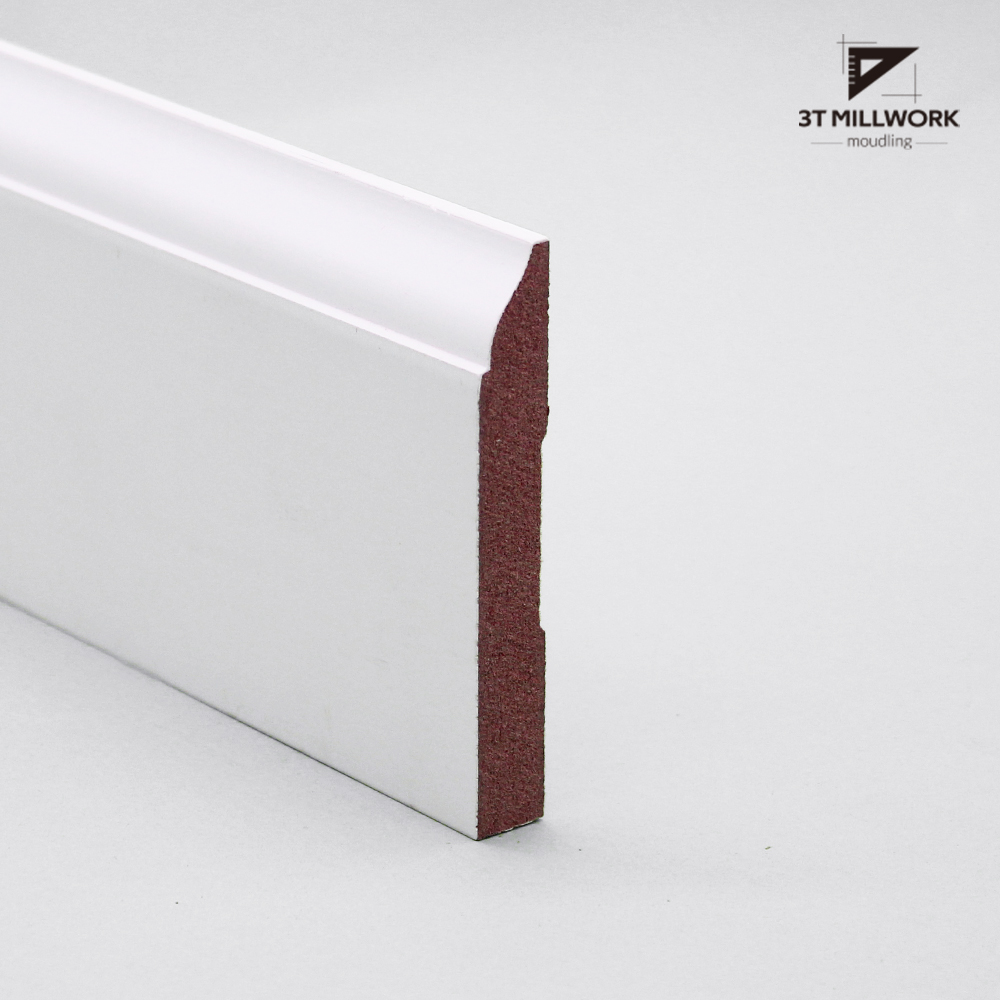

What is thin baseboard molding

Thin base board molding is a kind of product which is thinner and smaller which used for special places, the most thin moulding which we do are for wall panel and ceiling, the thickness is around 9mm(3/8 inch)with design and gap which for connection different panels together. Burt for a board which do not have designs on the surface, we can make more thinner like 3mm and 4 mm (1/8 inch). We have the machines and professional person whose do the production of these mouldings for you, you can trust us more for 3 inch baseboard moulding or 8 inch baseboard moulding and customized sizes moulding.

Light weight

The weight of the smaller and thinner moulding do have light weight that for different of your using in your house, some of them for decoration using with special construction. These lighter weight moulding can loading in the container with more quantity, allow you can get a very good price after average the shipping cost.

High cost

The more thinner moulding do have high cost during production, since they are easy damaged during each production process compare with the thicker moulding, so the price will be a little higher but not more for you, the price is the best that we can supply you since the professional production lines of us and you can come to talk with us for thinner stacked baseboard molding.

Various materials

There are so many materials that you can choose from us for thin baseboard moulding, birch baseboard trim, alder wood trim moulding are all can be get from us besides pine and MDF material moulding. But the materials of the thin moulding need to choose the super one to make sure the 16 foot or 5.4 meters length will not have any problems.

Types of wood material

Solid wood without knots

Solid wood without knots is a type of material which do have the highest grade during production, we have to choose the matched raw material for this types of moulding production, this is the A Grade material in the market and the price is very high not matter you choose them for 3 baseboard moulding or 5.5 inch baseboard trim transitions.

Solid wood with knots

This is a kind of material which still have high grade but easy to get in the market, the price is still high compare with the common materials, we can help our customers custom different wood species with this wood, for handrail, baseboard or stairs production, the price is depend on the quantity also.

Finger joint and splicing

Finger joint and splicing wood moulding is the common material in the market, the material is easy for production and the moulding price is also cheaper, especially for extra wide baseboard moulding or commercial baseboard molding production, the finger joint and splicing method need to be super to make sure they will not crack or broken during using.

Installation guild

Nailing

Most of our moulding are made more than 16 foot length, installing wood baseboard 16 ft by one person in the destination, the longer size of the moulding, the less connection point and the gap is hard to treat them with smooth, but you have to make sure the light weight and super quality of the moulding during installation that without crack and lighter. The smaller nails help installation the moulding quickly and easily, the smaller hole will nailing into the board with smaller holes on the surface, but they will smooth after you do painting after the installation, the big hole need to Secondary processing them and glue them to make them inside the closed environment without rust or visible.

Gluing

Installing baseboard inside corners with gluing is also super, the glue which you can get in the market easily, this method is very important for finished moulding during installation, since the nailing will leave smaller holes and damage the surface coating. Different method suit for different kinds of mouldings, we do not need to give more support and guild for this since most of our customers are agent, or they do have more professional experiences to help you to installing baseboards on rounded corners for you, you can come to us to know the agent and buying products from them if your quantity is less, they will helping you do that with different types of moulding.

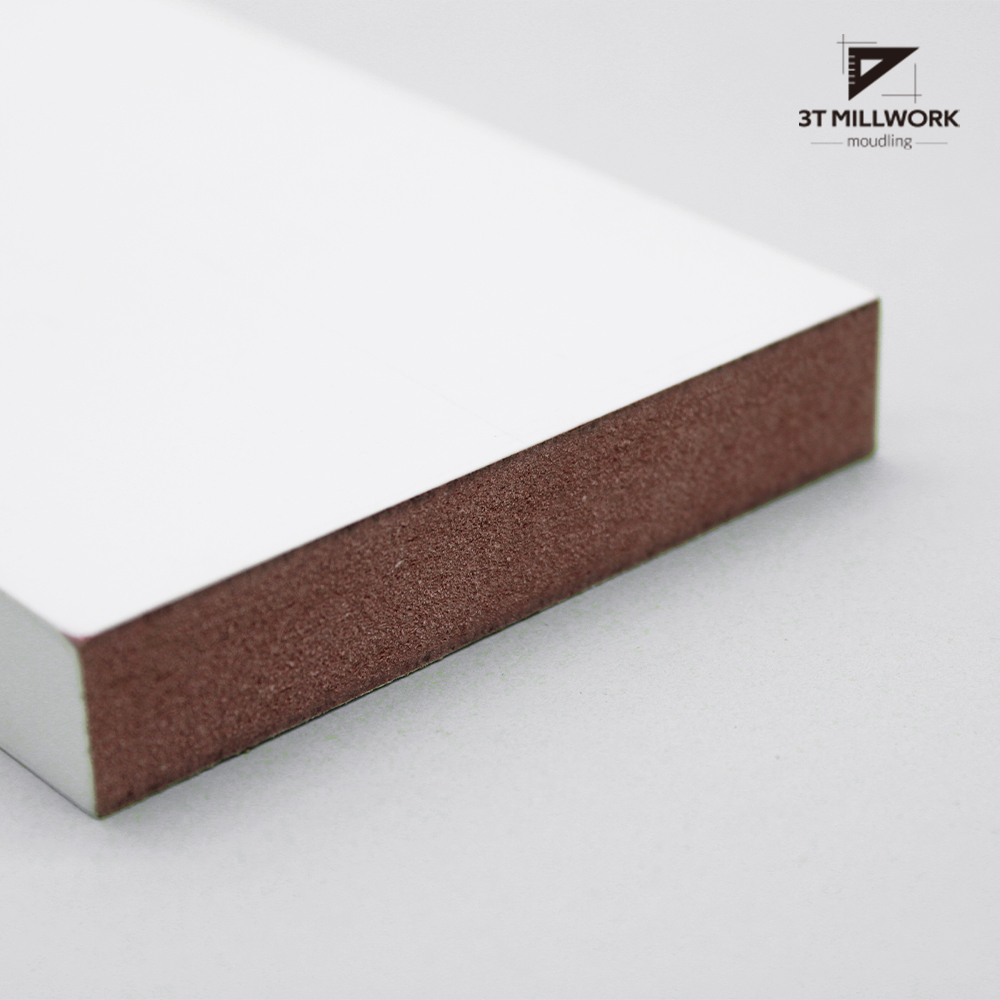

Types of MDF material

MDF

MDF material is the common material which the density is made from 600kg/CBM to 800kg/CBM, this density is heavy for longer moulding but suitable for door jamb or window frame with the shorter size, the nail holding ability is good and you do not worry about anything for installing baseboard corners in your places.

LDF

LDF material is the product which the density made from 480kg/CBM to 600kg/CBM, this kind of board do have high request of the wood fiber during production, so the price of the moulding is higher also. They are super material for the production of fancy baseboard molding in the market.

HDF

HDF is a super production but not for the production of moulding, they normally choose this material for flooring, wall panel, shelving of decoration in the market, the color of the HDF normally made with black and you also can get any other colors from us, the density is around 800kg/CBM to 1200kg/CBM and the furniture base moulding will broken if you choose this material.

Difference of surface treatment

Painting

Most of painting baseboards and quarter round are finished product which you can use them directly in your places, the price is a little higher than semi finished moulding, but it not means you can not change the color when you think they are not matching, you can do another paint on the surface to change the color with the wall or any other furniture together is available.

Primed

Primed historic baseboard molding or any other types moulding is the most poplar style for us, since the dealer can do the second painting or lamination on the surface which according to the request of yours, the price is cheaper for a primed moulding which you can easily do the painting or other treatment on the surface easily.

Lamination

Do the lamination on the surface of moulding is available, Plastic lamination moulding like bathtub baseboard molding or shower base moulding are water resistant, you can use them in a high moisture place to make sure they will not have any problem during using, we can supply finished moulding also but the base material is raw without primer for lamination moulding.

Veneer

Wood veneer is a kind of product which need to make them similar like real wood, most of the raw material are not wood or the wood do not have that high quality, so we can choose different species of wood veneer as the material when lamination, the finished wood veneer casing as baseboard to casing transition or any other moulding are hardly to tell they are wood or other materials.

get support from us

Price promise

Price can be got promised for all kinds of our moulding, no matter for baseboard, crown or step bevel baseboard molding, we can control the low cost of the production and give support for different designs, different sizes of the moulding during production, with our mature production staff and advanced machines, this give a possible to supply good price for you.

Quality guaranteed

The quality of the porcelain baseboard molding can be get promised since our more than 20 years production processes, you do not need send someone to us for quality checking, we can take all of the risks for the quality problems, you do not need to worry about anything of this, the highest production standard are here in our factory.

In time delivery

The in time delivery is necessary especially for a big order of yours per month, we can helping you control the least stocks for saving money with our reasonable and in time shipment, you can buy mixed types of installing flat baseboard which made by wood or MDF from us, we do not have any limited of the design of the moulding since we are factory, helping you lowest stocks for each model also for saving money.

Shipment support

The shipment of the rimu mouldings and 6 baseboard molding can be supported by us with DDP and DDU terms, you can leave your work to us and we can helping you with all of the paperwork, custom clearance, tax and destination shipment, take the risks for all of these steps for you with the lowest cost, you can relay on us for the shipment as well as the quality of the moulding.