Description

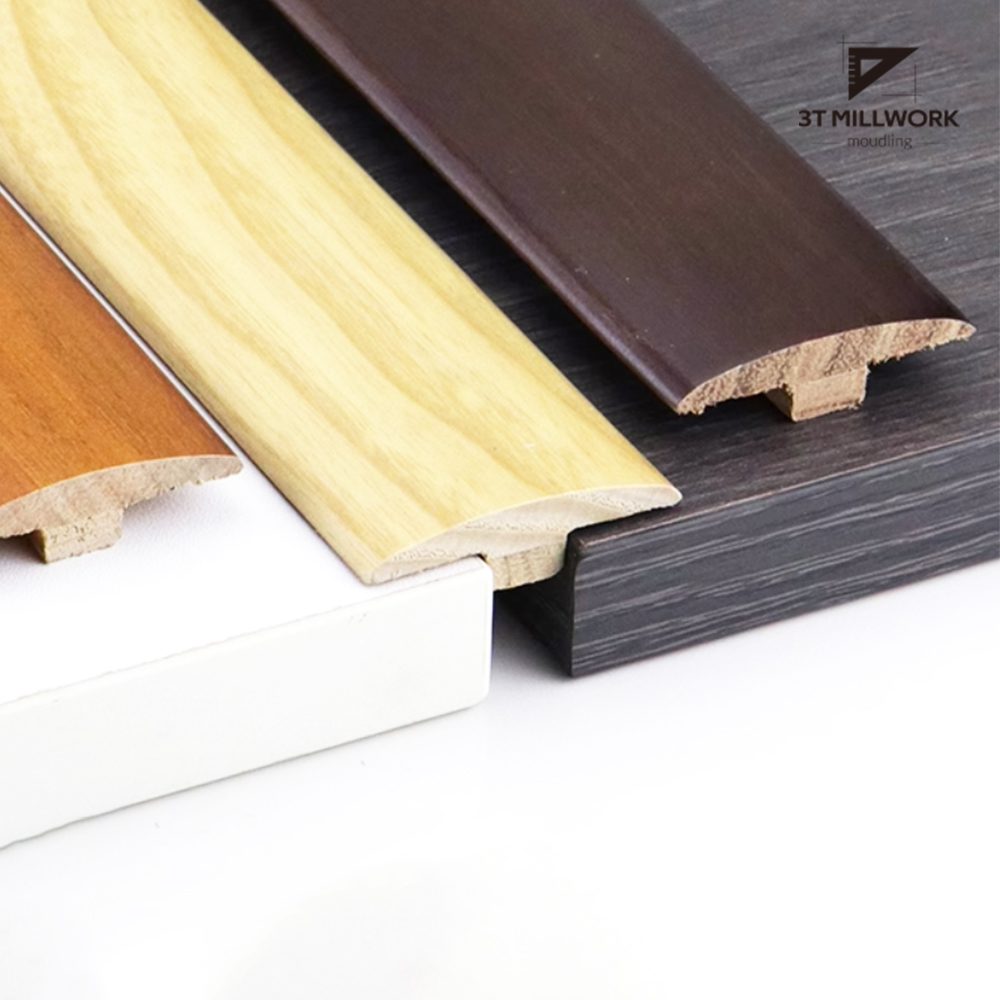

What is wood floor moulding

Wood floor moulding, also known as trim or molding, is a type of decorative and functional element used in flooring installations. It serves several purposes, including covering gaps between different flooring materials, concealing expansion spaces, providing transitions between different rooms or flooring types, and adding a finishing touch to the edges of the flooring. Wooden floor door trim is available in various profiles, sizes, and species of wood to match different flooring styles and design preferences.

Aesthetic appeal

Wood edge molding has a naturally beautiful grain pattern and rich color that adds visual appeal to any space. Oak T-moulding can be stained or finished to match the flooring it is installed alongside, creating a seamless transition and a cohesive look in the room.

Customization

Wood floor t molding can be cut, shaped, and finished to meet specific design requirements. Whether you need a straight transition between two flooring types or a curved transition around a corner, oak T-moulding can be customized to fit your needs.

Value

While oak T-moulding may have a higher upfront cost compared to some alternative materials, its durability and timeless aesthetic can add value to your home in the long run. Additionally, oak is a sustainable and renewable resource, making it an environmentally friendly choice for trim and edge moulding wood.

Strength of our company

Material Sourcing and Supply Chain Management

Establishing strong relationships with reliable suppliers and efficient supply chain management can ensure a steady supply of high-quality raw materials at competitive prices.

Market Knowledge and Adaptability

Understanding market trends, customer preferences, and industry developments allows the factory to adapt its wood flooring door trim and processes to meet changing demands effectively.

Cost Efficiency and Operational Excellence

Implementing lean manufacturing principles and optimizing operational processes can improve efficiency, reduce waste, and lower t molding tile to wood production costs.

Why Choose us

Consistency and Quality Control

Factories often have robust quality control measures in place to ensure consistency and wood reducer molding quality across large production runs. This reliability is essential for meeting customer expectations and maintaining brand reputation.

Speed and Timeliness

Factories are equipped to produce white floor trim with wood door trim at a faster pace than smaller-scale operations, enabling quicker turnaround times for orders and shorter lead times for customers.

Resource Optimization

Factories can optimize the use of resources such as raw materials, labor, and energy, leading to reduced waste and improved efficiency in wood floor shoe molding production processes.

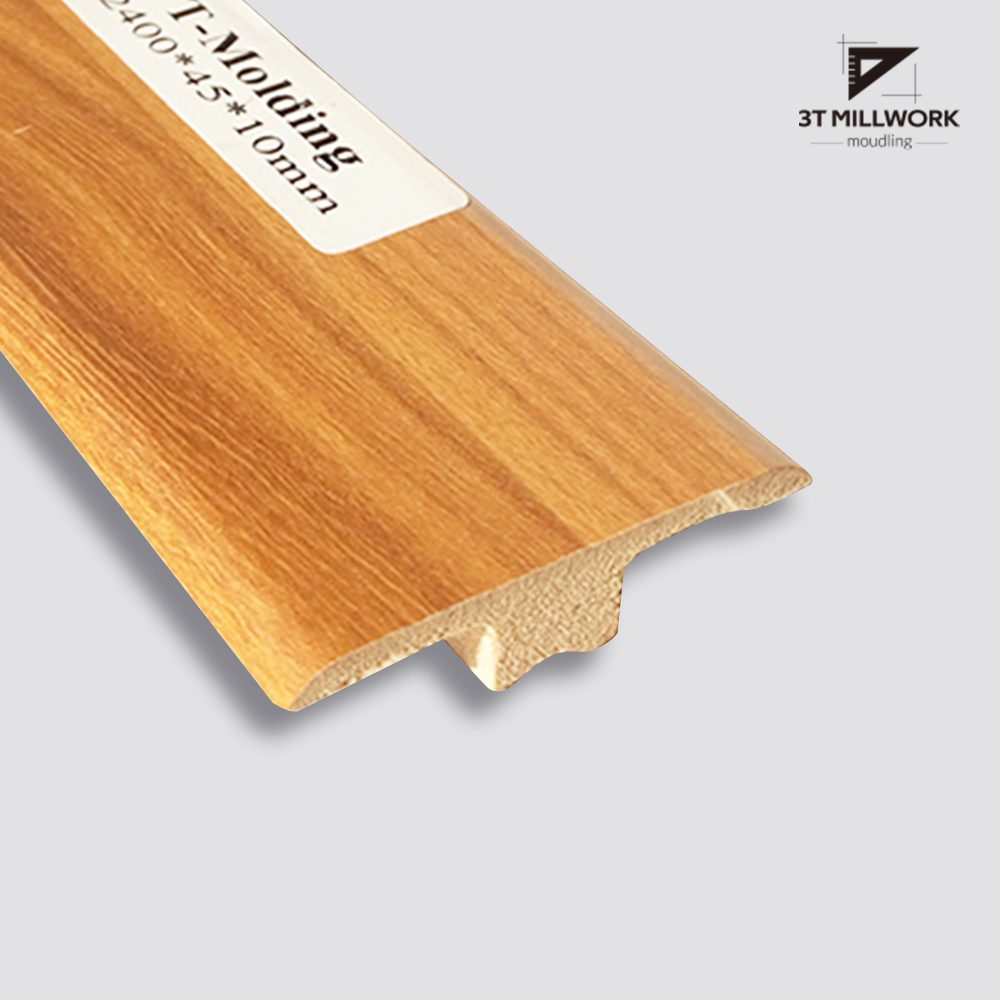

Details of wood floor moulding

Installation

Wood floor threshold molding is installed using adhesive, nails, or screws, depending on the subfloor material and installation requirements. It is typically positioned in the seam between the two flooring materials, with the top of the T flush with the surface of the flooring.

Applications

wood floor molding profiles are suitable for use with a wide range of flooring materials, including hardwood, laminate, tile, vinyl, and carpet. It provides a smooth transition between different flooring surfaces while also protecting the edges from damage.

Maintenance

Wood floor molding types requires minimal maintenance but should be periodically cleaned and inspected for signs of wear or damage. Regular dusting or vacuuming can help maintain its appearance, while spills should be promptly wiped clean to prevent staining.

Specification of wood floor moulding

Packing Details

Package are made by pallet, each pack do have pe film with log printed for the outer of the moulding, you can customized any special package with shrink and corrugated with us.

Production Capacity

We can do more than 200 containers moulding per month, end molding wood floor or l molding wood are smaller size and they take longer time for production.

Name

Our moulding do have different names like wood cap molding or door trims for wooden floors, they named with different depend on the place using in different market.

Wood species

Softwood and hardwood are both available for us, you can choose any wood species from us even they are special like walnut, oak or poplar.

Application of wood floor moulding

1

Expansion Gaps

During the installation of floating floors, such as laminate or engineered hardwood, a small expansion gap is typically left around the perimeter of the room to allow for natural expansion and contraction of the flooring material. Wood floor reducer molding can be used to cover and conceal this gap while still allowing for the necessary movement of the flooring.

2

Finishing Touches

Wood floor end molding serves as a finishing touch in flooring installations, providing a clean and polished look to the edges of the flooring. It adds a decorative element while also protecting the edges from damage, such as chipping or splintering.

3

Stair Nosing

In some cases, wood floor molding can be used as stair nosing to provide a finished edge on stair treads. While stair nosing profiles are specifically designed for this purpose, wood t molding can be adapted for use on stairs in certain situations, particularly if a consistent look is desired throughout the space.

What other moulding you can buy from us