Description

What is MDF quarter round

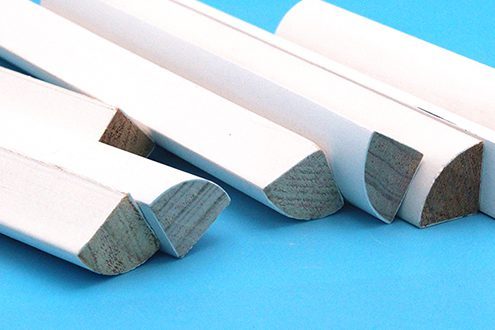

Mdf quadrant beading is very popular since it starts to used as the building material, because its acceptable price and durability. Our MDF moulding is with the low density and strong flexibility. The flexibility of our products can be tested by fishing test. It can be bent like a fishing rod without breaking. These are two important features of the moulding product. The low density means the weight of same size moulding is light, it is more easy to carry and transport, especially when you install the moulding, you will find the light weight and strong flexibility can save much time and labor.

Our white mdf quadrant beading is one of popular moulding products. Its size is small and price is cheap but it can be used in many place to cover the gap and imperfection well. The common usage is to cover the gap where the baseboard meets the floor. It not only can be as a seamless connection among the baseboard and floor, but also can prevent the dirty from falling into the gap to make your house clean. What`s more, when you cover the gap can protect the edge of the fragile floor edges and baseboard bottoms from bumping.

More quantity loading

The low density of mdf quadrant moulding also makes big difference to the shipping cost. For the area where has the weight limitation of the container wight, the low density means you can load more quantity into the container, that can reduce the shipping cost of each feet. That can make the moulding price more competitive.

Low cost

The MDF quarter round moulding is a smaller product which loss in the production process will be slightly more, because it may be broken if you are not careful. In this situation, it is difficult to reduce product prices through raw material costs, so only by continuously optimizing the quality of raw materials and reducing the density to reduce transportation costs is an option to reduce product quality.

Size do not have limited

Since the smaller type of the moulding, most of the factory can not supply you a very big length for the mdf quarter round molding, but we now already solve the problems till now and Our goal is supply the good quality product with low price, so welcome to cooperate with us, we will try best to make your products more popular with customers.

Strength of our company

We are mdf board factory

Choose MDF half round mdf moulding products from a MDF board factory will give your more advantages, the price can be more cheaper besides the high quality of the material, we do know much better of feature of the material and produce high quality raw materials.

We have huge area for production

The quantity is much bigger especially for MDF primed quadrant beading and the price is cheaper, the market is much bigger of these kinds of products, so you can give us your huge order to us and we can supply you good delivery time and high quality moulding.

We have more professional workers

Most of our workers are come from our MDF workshop and few of them come from our old factory which doing solid wood products, you do not need to worry about quality and any other specifications of our primed quadrant moulding.

Why Choose us

- Reasonable price: The price is much better in our factory, you can get our price list for any types of quarter round molding and the shapes can be chosen with different on the surface, good price will help you get more bigger market.

- High quality material: The quality is more good since we are a factory for MDF board, no extra shipping cost and also free warehouse and land for using, the base cost is less and allow us to supply you good price.

- No limited moulding size: Compare with the bigger size of MDF quadrant architrave, smaller size moulding do have more high request of the raw material, but the size of MDF quarter round moulding do not have any limited since the high quality of raw material.

Details of MDF moulding

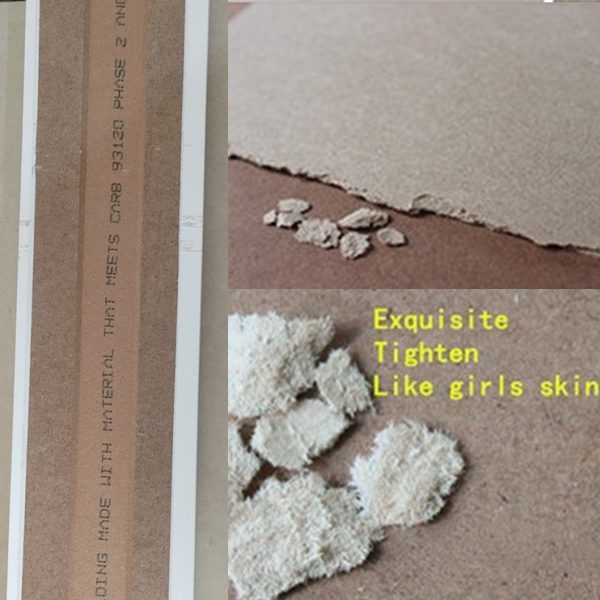

Low density

The density of the mdf can be made with different and they are easy to adjustment during production, the density can be made with 580kg/CBM to 1020kg/CBM, low density allow you can loading more in the container, but you have to make it more stronger with low density, we are the only one factory can supply you 580kg/CBM density material for your moulding, both smaller and bigger size mouldings.

Thinner coating

It is more easier to do primed on the surface of mdf moulding compare with solid wood, without any other production process like wood material, the production time will be saved much and more quicker for mdf moulding. The coating layer can be more thinner since the surface is much flat of mdf, they are more stronger and they are not easy broken during shipping and installation.

Durable using

Our mdf material is as stronger as solid wood, you can use it for any places including for door jamb, the material is very good to allow you do hole with lock or hinges on it. Use the high quality material with cheapest price for your home decoration or renovate a house are both available, do not hesitate to let us know more of your requests and we will make them more durable for you.

Material type for moulding

Mdf

The mdf half round moulding is much better compare with half round lumber moulding, the size can be make with 16feet and they are not easy crack and stronger like solid wood material.

LDF

LDF do have low density but high quality in our factory, we use LDF do 16 feet moulding and use MDF material for 8 feet and 12 feet moulding since the moulding is much smaller and easy crack.

Types of MDF moulding

Primed

No matter you buy our 9mm quadrant moulding or 35mm quarter round, all of them can be made with primed treatment on the surface, and this method is the main production in our factory and most popular in the market.

Lamination

Lamination with veneer or paper are both ok for maple quarter round molding or MDF moulding, the colors can be chosen with different from us and the price also be very different for different kinds of lamination.

Painting

Painting with base coat or face paint are both ok for us, you can choose any of them from us for your moulding, to make them from semi finished products into finished moulding and can use them directly.

Material introduction