Description

What is floor moulding

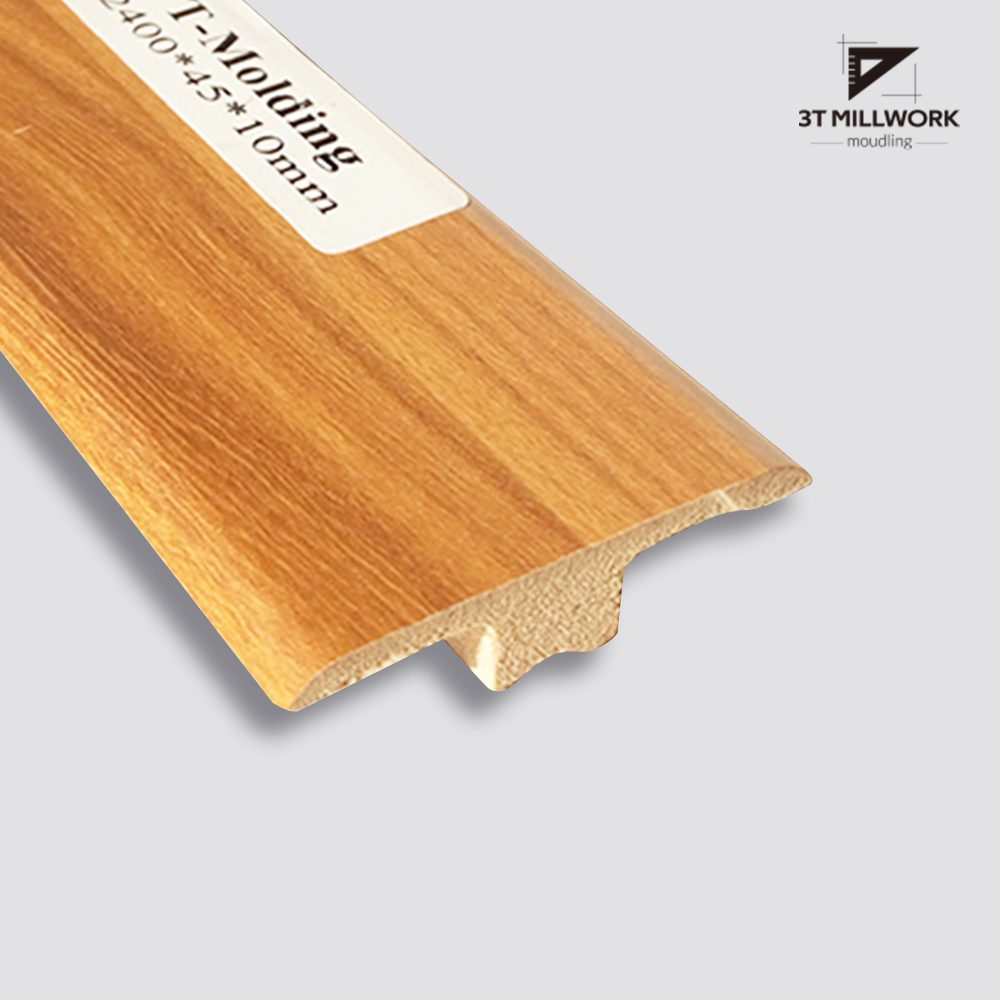

The transition floor moulding corners are essential part for your floor project and Because of the special feature of the wood floor, you need to leave some gap for the floor to meet the floor shrinkage and expansion. The door floor trim moulding can be used to cover any gap between the floor and the wall and the baseboard.

The wide floor molding size and style can be customized, so whether kinds of moulding is ok for us , we can make the product for your special need. The CAD drawing according to your requirement on the installing floor moulding specification can be made before the production, when you confirm the drawing, the product will be total same as the drawing. There is no size error and every detail will be exactly the same as the drawing.

Our moulding is made from the raw materials with good quality. The common materials are the MDF and various kinds of wood.

Stable quality

These materials are all supplied by our long-term cooperation partner. We seldom change the supplier of the raw material, that can ensures the stability of material quality. So our moulding quality will also be stable.

Multiple types

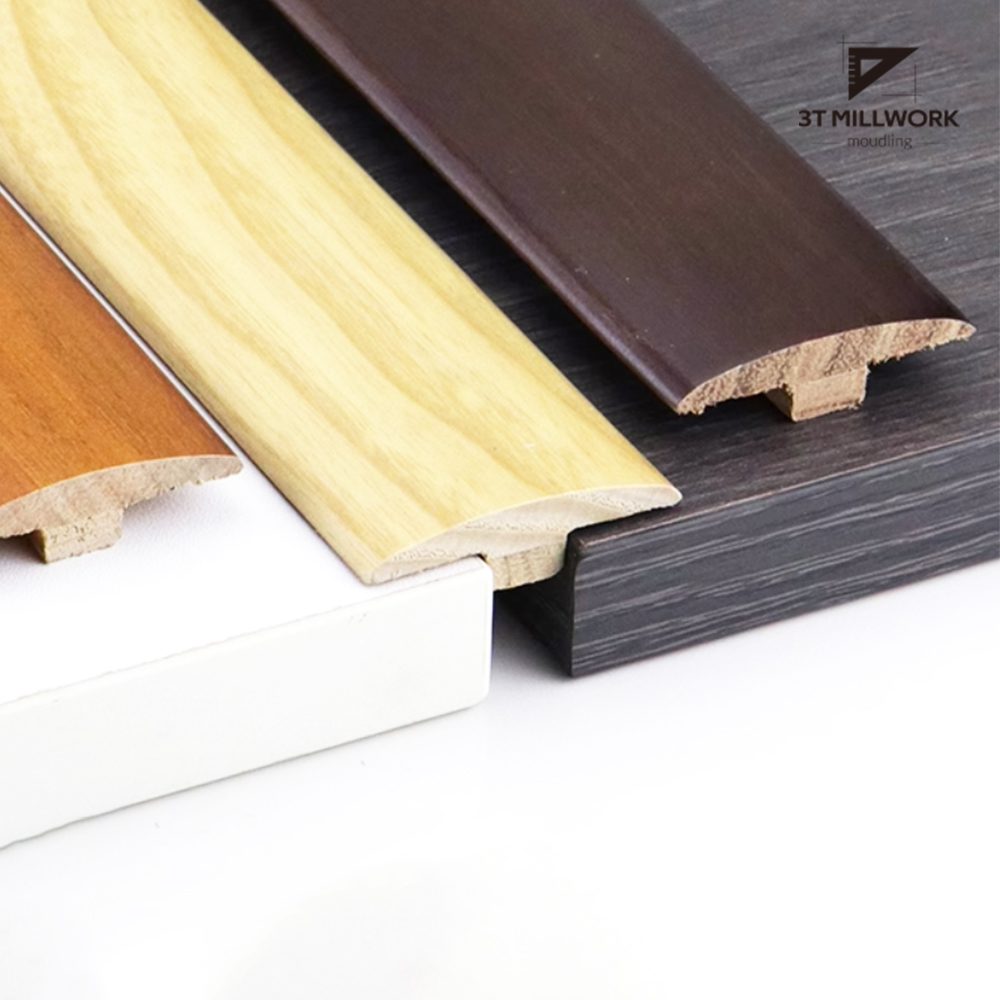

There are different choices of the door floor edge trim surface, it can be with the wood natural color or primed. It also can be painted and stained with the color to match your home existing decorative style.

Professional team

Our factory has been produced different kinds of door floor moulding for more than 10 years. The workers are also experienced in the moulding product and know well how to make the product quality.

Super treatment

We can guarantee our product quality will not let you down. When you receive the product, you will find the surface is with good treatment, they are all clean and smooth. It can be install directly and no need extra treatment.

Strength of our company

Super coating

The primed or the paint coating are more super and thin, they are very stronger and will not crack easily during using, you can hardly find a factory can do this super coating in the world.

Good method of finger joint

We know much familiar for the finger joint ways, to make sure the moulding do have good feature and not easy broken in a very longer length.

LDF material do have good fiber

LDF material is the one of our main material in our factory, the fiber is the core to make sure the quality of the moulding, to make sure the products is not easy to crack and broken.

Good treatment of knotty

The coating easy floor molding will be have problems if the knotty do not have a good treatment, we normally cutting them off and move the knotty, or use special treatment to make sure it will not have problems in using after years.

Why Choose us

Sample policy

We supply free samples for all of our customers especially our cooperated customers, you can get our samples in 5 days and sometimes you can get the shipping cost free which the cost will be borne by our company, so why you wait now and contact with us today.

Shipping support

Most of the factories only can do FOB term for you, but we can give a very super price for CIF, DDU and DDP, even you can get a very good price with our EXW term, you can choose any of these term for delivery your farmhouse floor molding, all of the risk will be bear by us.

Quick replying and easy understanding

Almost all of our office workers can speak little of english, so you do not need to worry about any communication problems even you are not speaking English, we can give a very quick replying by the languages which belong to yours with the professional translator.

Application of floor moulding

1

Finish and Transition

Floor base moulding provides a finished look to the junction between the floor and the wall. It can create a smooth transition between different flooring materials or cover any gaps or imperfections in the flooring.

2

Architectural Detail

Molding adds architectural detail to a room, enhancing its overall aesthetic appeal. Different styles of floor board molding, such as crown molding or chair rails, can contribute to the character and style of the space.

3

Visual Interest

Molding comes in various designs, from simple and modern to ornate and traditional. This diversity allows homeowners to choose a style that complements the overall design theme of the room.

Types of floor moulding

Primed with base coating moulding

Most of our floor nose molding are doing with this treatment, they are doing with a reasonable treatment cause you have to paint different colors after you installation the moulding in your house. The base paint is doing for ready for the last paint, you can paint the last one layer with face paint directly.

Finished painting moulding

Doing the finished painting on the surface of the floor shoe moulding will make the products can be used directly, the colors can be white and you can change the color easily if you want, you also can do the different colors by the paint in our own factory, the size can be customized as well as the colors.

Veneered moulding

This is a method with high cost to make a finished floor wall moulding, the material is come from nature wood and the color or the texture are both keep same with the raw wood. You can do veneer on wood moulding and you also can do the veneer on LDF moulding, are all super products for your using.

Lamination moulding

Lamination the floor side molding with paper or plastic are both ok, the color of the paper and plastic filming are both can be printed with different. The wood grain colors are the most popular color in the market, you can choose each one you like and each color you want.

Material for floor moulding

MDF material moulding

This material is the tradition material in China, we do not suggest you do much longer with this MDF material, no more than 8 feet will make sure the floor to wall molding will not broken during using or it will have risks due to the heavy density.

LDF material moulding

This is a new products in our own factory, we do the raw material ourselves with light density but more stronger material, to allow us can supply you the nose floor moulding with 5400 mm and it will not broken in using.

Pine wood moulding

Pine is the most popular material in the market and it come from New Zealand mostly, the good feature and the price make it more popular for modern floor moulding products, length can be made more for you.

Poplar wood moulding

Cause most of our poplar material are come from local places, low cost and the price is a little cheaper than pine, but the density is not as good as pine for supply a good nail holding for you during using.

What other products that you can buy from us

Add more beauty for your home decor

The color can be matched with your door of the trim, you can use white color or wood grain color and they add more decor elements for your house, make your house do have more characters and elegance.

Make you room more clean after cover the gaps

The gap will be have between the connection of the floor and the wall, so this moulding is necessary in your house when you furnish your house, it is necessary product and can make your room more clean to cover all gaps.

Give more space for the shapes changes for the floor

The floor trim is used for a transition, as the temperature changes in a year, the size of the floor will be a little changed, and you do not need to worry about it after you use the flooring trim.

How to installation our floor moulding

01

Cleaning

You have to clean the places where you want to installation the moulding, you need to keep the places in a dry, clean and flat situation which ready for installation.

02

Cut the correct size

You have to measure the size of the installation places and cut the moulding which can match this size, the size need to be in a correct size and ready for installation.

03

Installing

You can installing the moulding after you prepare the previous two steps, use nails or glues to make the moulding installation with a tight way.

04

Fulfill the gaps or holes

You have to use the special material to fulfill the connection gaps or the holes of the nails, make sure each places of the holes and gaps in a solid situation.

05

Sanding

When the fulfilled materials are drying, you have to sanded them by hand to make them more smooth and flat which keep with the same surface with moulding itself.

06

Painting

You have to paint the surface of the moulding to make sure the color can be matched with any other furniture, make them uniform when you painting them and protect other parts which next to your painting.