Description

What is hardwood t moulding

Hardwood floor end cap molding, often simply referred to as T-moulding, is a type of transition moulding used in flooring installations. It is specifically designed to create a smooth transition between two different types of hardwood flooring or between hardwood flooring and another type of flooring material, such as tile, laminate, or carpet.

Overall, best deal hardwood floor & moulding provides both functional and aesthetic benefits in flooring installations, allowing for smooth transitions between different flooring surfaces and adding a finishing touch to the overall design of the space.

Durability

Hardwood t molding between hardwood and tile is made from solid hardwood, which is known for its durability and longevity. It can withstand regular foot traffic, impacts, and other wear and tear, ensuring that transitions between flooring surfaces remain intact over time.

Strength

Hardwood studio molding and hardwood flooring provides structural integrity and stability to flooring transitions. Its solid construction and resistance to warping or twisting make it a reliable choice for maintaining the integrity of the flooring installation.

Aesthetic Appeal

Hardwood floor reducer molding adds a touch of elegance and sophistication to flooring transitions. Its natural wood grain, texture, and finish enhance the overall aesthetic of the space, creating a seamless and cohesive look between different flooring materials.

Strength of our company

Strong Reputation and Brand Recognition

A solid reputation for delivering high-quality t molding hardwood, excellent customer service, and reliability can contribute to brand loyalty and attract new customers through word-of-mouth referrals.

Compliance with Regulations and Standards

Ensuring compliance with industry regulations, safety standards, and environmental sustainability practices not only enhances credibility but also minimizes risks and liabilities.

Continuous Improvement Culture

Fostering a culture of innovation, learning, and continuous improvement empowers employees to identify opportunities for optimization and stay ahead of the competition.

Why Choose us

Cost Efficiency and Cost Savings

By centralizing production processes and optimizing workflow efficiencies, factories can often achieve cost savings compared to decentralized or smaller-scale operations. These timber angle trim cost efficiencies can translate into competitive pricing for consumers or higher margins for businesses.

Compliance and Standards

Established factories are more likely to comply with industry regulations, safety standards, and environmental requirements. This compliance reduces risks and liabilities for businesses and ensures ethical and sustainable manufacturing practices, especially our lumber liquidators molding.

Focus on Core Competencies

Outsourcing manufacturing to a factory allows businesses to focus on their core competencies, such as timber t moulding design, marketing, and distribution, while leaving the lumber liquidators moulding production aspect to experts in the field.

Risk Mitigation

Leveraging a factory’s expertise and infrastructure can mitigate risks associated with in-house manufacturing, such as equipment maintenance, workforce management, and market fluctuations. We will be your good partner for cherry wood trim moulding, promise good quality for you also.

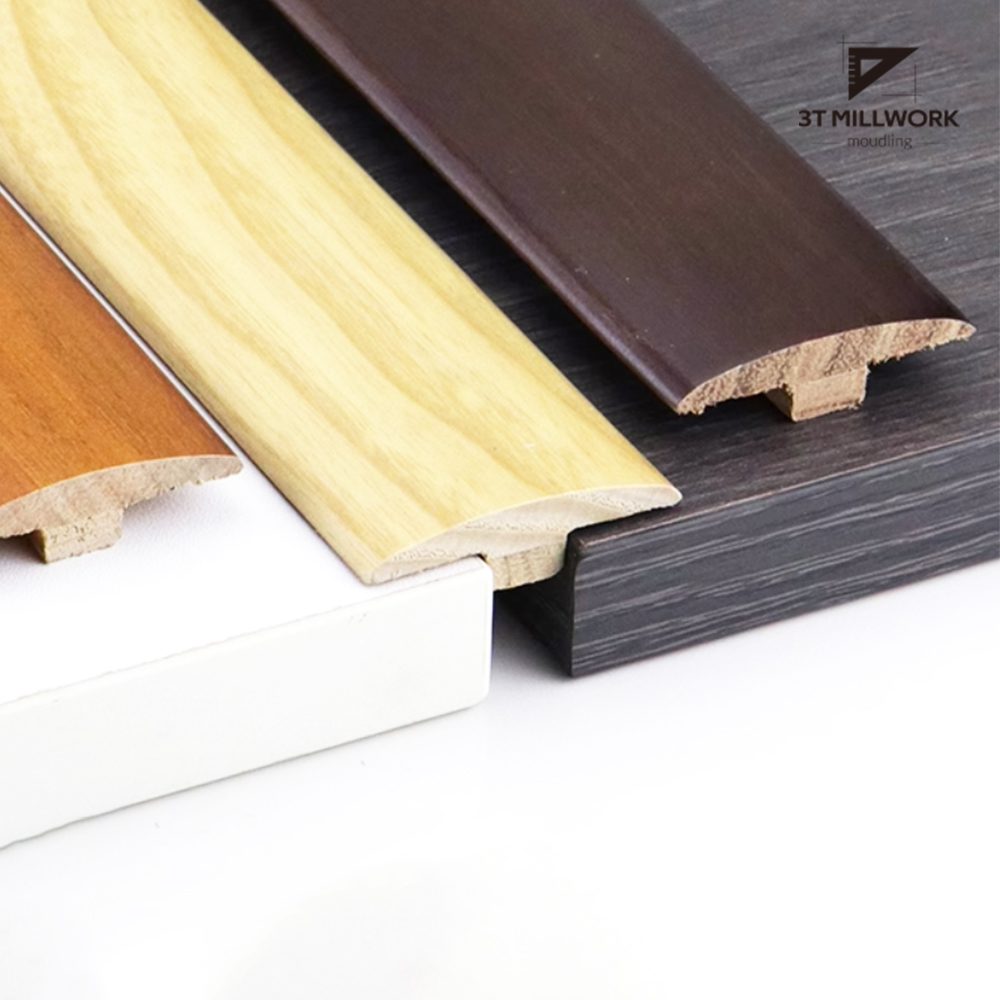

Details of hardwood t moulding

Material

Made from hardwood floor molding, typically matching or complementing the species of hardwood used in the flooring. Common hardwood species include oak, maple, cherry, walnut, and hickory.

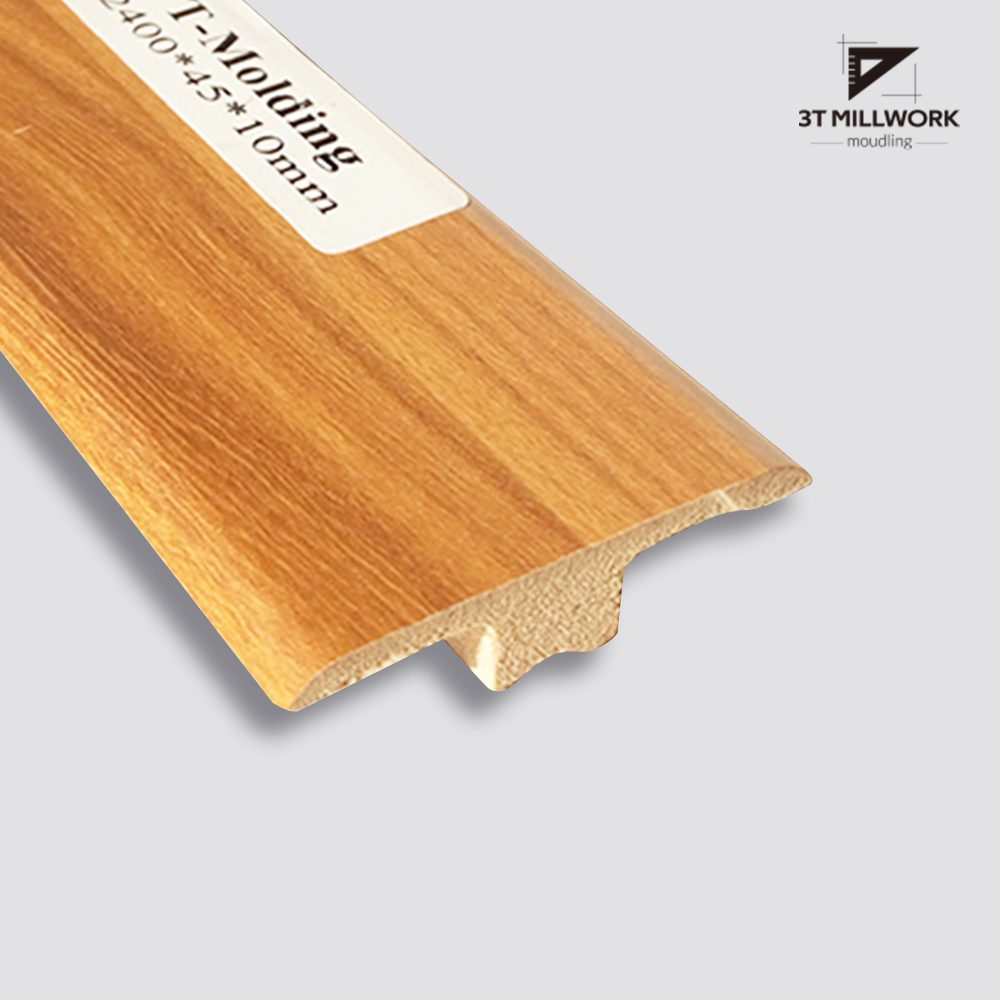

Profile

Hardwood trim molding has a distinctive “T” shape, with one side covering the edge of one type of flooring and the other side covering the edge of the adjacent flooring material. The top of the T is typically flush with the surface of the flooring.

Finish

Pre-finished with a stain and/or clear coat to match the finish of the hardwood floor molding types it accompanies. Common finishes include natural, stained, and clear-coated options.

Specification of hardwood t moulding

Surface Finish

There are many different surface finished method for hardwood floor t molding, primed, painting and lamination are all can be done in our factory.

Moisture content

The hardwood floor door trim need to control a very good and stable moisture content for the raw material, so you can get a very good and durable finished products.

Main market

Our molding hardwood floors main market is USA, Australia, Canada and New Zealand, we do have any other market in the world but the quantity is not that big.

Relative products

Besides the different designs of the moulding, you can get our birch t molding, mahogany moulding, walnut t molding, maple t moulding and hickory t moulding from us.

Types of hardwood t moulding

Standard T-Moulding

This is the most basic type of brazilian cherry t molding, featuring a straight “T” profile with a flat top. It is typically used for straight transitions between two flooring surfaces of the same height or for covering expansion gaps in floating floors.

Reducer T-Moulding

Reducer brazilian cherry shoe molding, also known as transition T-moulding, is designed to transition between two flooring surfaces of different heights. It has a gradual slope on one side of the “T” shape, allowing for a smooth transition from a higher to a lower surface.

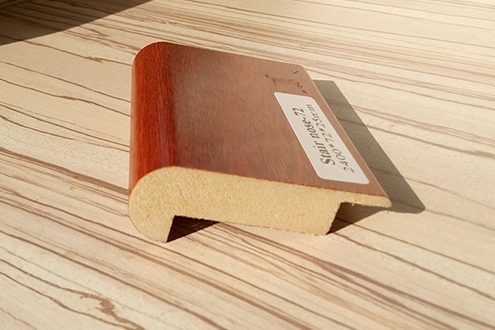

what other mouldings you can buy from us

Reducer Moulding

Reducer hickory trim moulding, also known as transition moulding, is used to transition between two flooring surfaces of different heights. It has a sloped profile that provides a smooth transition from a higher to a lower surface.

Threshold Moulding

Threshold hickory threshold molding, also known as door threshold or transition strip, is installed at doorways to cover the gap between two flooring surfaces. It provides a smooth transition between rooms and helps to prevent tripping hazards.

Stair Nose Moulding

Stair nose natural hickory t molding, also known as stair nosing, is specifically designed for use on stair treads to provide a finished edge and improve safety by reducing the risk of tripping. It typically features a rounded or bullnose profile that covers the edge of the stair tread.

How to customize hardwood t moulding

- Wood Species:

Choose a hardwood species that matches or complements the hardwood flooring you are installing. Popular options include oak, maple, cherry, walnut, and hickory. Consider factors such as color, grain pattern, and durability for molding between carpet and hardwood when selecting the wood species.

- Dimensions:

Hardwood unfinished hickory t molding comes in various widths, thicknesses, and lengths. You can customize these dimensions to ensure a perfect fit for your flooring installation. Measure the height and thickness of your flooring materials to determine the appropriate dimensions for the molding between tile and hardwood.

- Finish:

Customize the finish of the hardwood unfinished maple t molding to match the finish of your hardwood flooring. You can choose from natural, stained, or clear-coated finishes to achieve a cohesive look. Consider the sheen level (e.g., matte, satin, semi-gloss, or high-gloss) to complement the finish of your flooring.