Description

What is oak t moulding

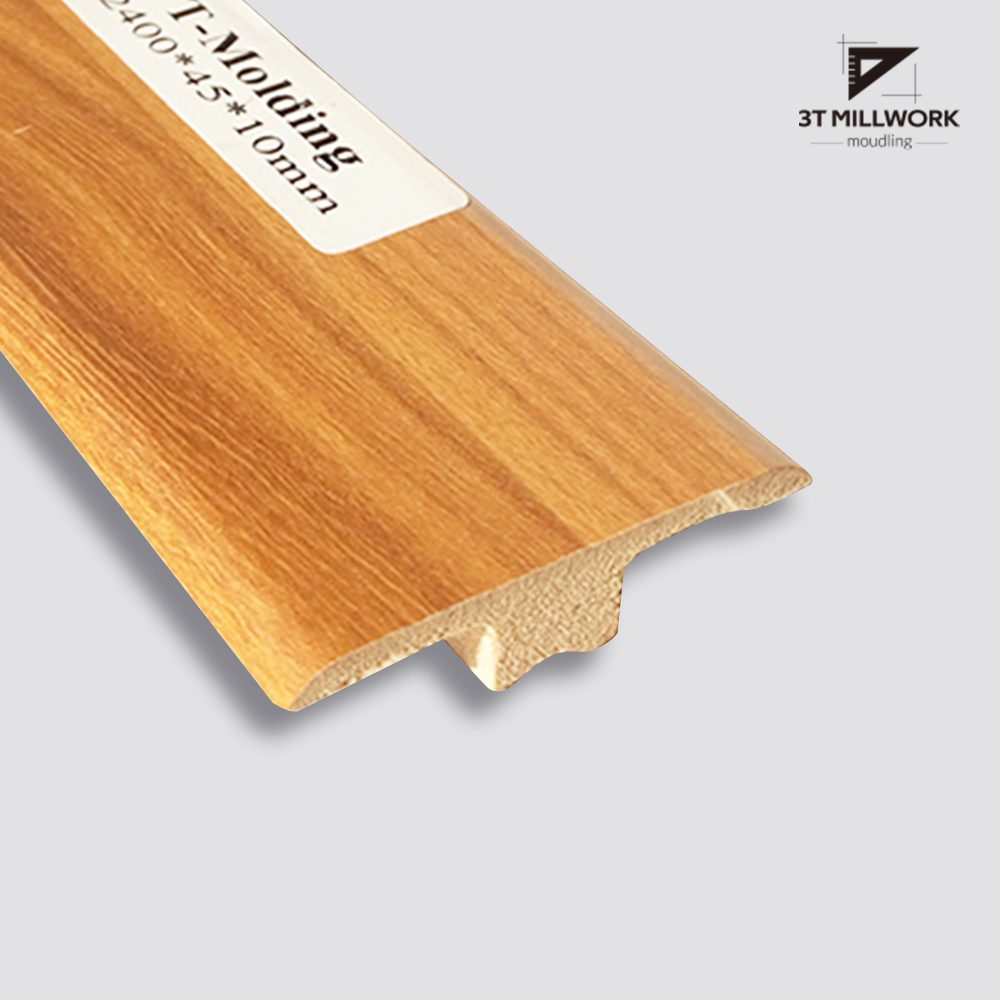

Oak T-moulding, also known simply as T-moulding or oak transition molding, is a type of trim or molding commonly used in flooring installations. It serves as a transition piece between two different types of flooring materials or between two rooms where the flooring materials change.

The “T” shape of the moulding allows it to fit neatly between the two surfaces, with one side covering the edge of one type of flooring and the other side covering the edge of the adjacent flooring material. This helps to create a smooth, seamless transition between the two surfaces while also providing protection for the edges of the flooring.

Oak T-moulding is specifically made from oak wood, providing durability and aesthetic appeal. Oak is a popular choice for flooring reducer molding due to its strength, hardness, and attractive grain pattern. It can be stained or finished to match the flooring it is installed alongside, creating a cohesive look in the space.

Durability

Oak is a hardwood known for its durability and resistance to wear and tear. Oak floor transition moulding provides long-lasting protection for the edges of the flooring, helping to prevent damage from foot traffic, furniture, and other sources.

Stability

Oak saddle threshold moulding is less prone to warping or twisting compared to softer woods or alternative materials. This stability ensures that the transition between flooring types remains intact over time.

Versatility

Oak floor molding can be used with a wide range of flooring materials, including hardwood, laminate, tile, and vinyl. Its versatile design allows for easy installation in various environments and applications.

Strength of our company

Advanced Machinery and Technology

Having state-of-the-art machinery and equipment can enhance production efficiency and output quality. This includes precision cutting tools, molding machines, and finishing equipment for a gunstock oak t molding.

Skilled Workforce

A factory with highly skilled and experienced workers can ensure high-quality craftsmanship and efficient red oak t moulding production processes. Expertise in woodworking techniques, machinery operation, and quality control is essential.

Customization Capabilities

The ability to offer customized oak reducer floor moulding solutions to meet the unique requirements of customers can be a significant strength. This includes flexibility in design, material selection, and finishing options.

Quality Control Procedures

Implementing rigorous quality control procedures throughout the manufacturing process ensures that the final reducer floor moulding meet industry standards and customer expectations. This includes inspection checkpoints at various stages of production.

Why Choose us

Economies of Scale

Factories enable mass production, which often leads to lower per-unit costs due to economies of scale. Producing reducer molding in large quantities can reduce manufacturing costs per unit, making the products more affordable for consumers or more profitable for businesses.

Specialized Equipment and Expertise

Factories typically have specialized machinery, equipment, and skilled labor dedicated to specific manufacturing processes. This expertise and infrastructure allow for efficient reducer threshold molding production and high-quality output that may not be achievable in smaller-scale operations.

Capacity and Scalability

Factories have the capacity to handle large volumes of flush mount reducer molding production, making them suitable for scaling up production to meet growing demand or seasonal fluctuations. This scalability provides businesses with flexibility and agility in responding to market changes.

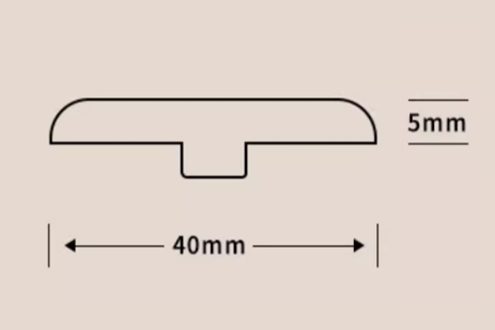

Details of oak t moulding

Size

Unfinished oak shoe molding comes in various sizes to accommodate different flooring heights and thicknesses. Standard sizes typically range from 0.5 inches to 2 inches in width and 0.25 inches to 0.75 inches in thickness.

Length

White oak t molding is often sold in standard lengths, typically ranging from 6 feet to 12 feet. However, custom lengths may also be available to accommodate specific installation requirements.

Finish

Oak reducer moulding flooring is typically available pre-finished with a stain and/or clear coat to enhance its appearance and protect the wood from moisture, scratches, and wear. Common finishes include natural, stained, and clear-coated options.

Specification of oak t moulding

Payment

Payment terms do have more for choice with cash, TT payment or L/C payment are both available for us, you can choose any other kinds of payment terms for unfinished reducer molding order.

Size

Size can be done with extra wide and extra longer for you, thickness also do not have any limited during reducer molding floor and decor production, you can get any sizes of moulding from us.

Logo

Logo can be customized on package and also can be done on the t moulding reducer, you can customized special moulding as well as the special package.

Samples Time

Sample of carpet reducer moulding supplied with free for you, the delivery time will take around 1 to 2 weeks, special sample can be get from us also as your requirement.

Application of oak t moulding

Transition Between Different Flooring Materials

One of the primary applications of sterling oak t molding is to create a smooth transition between two different types of flooring materials. For example, when transitioning from hardwood flooring to tile or carpet, T-moulding provides a seamless transition that covers the edge of each material, creating a polished look.

Room-to-Room Transitions

In homes or commercial spaces where different rooms have different types of flooring, such as hardwood in one room and laminate in another, red oak t molding can be used at doorways or thresholds to bridge the gap between the two floors. This helps to maintain continuity in design while also preventing tripping hazards.

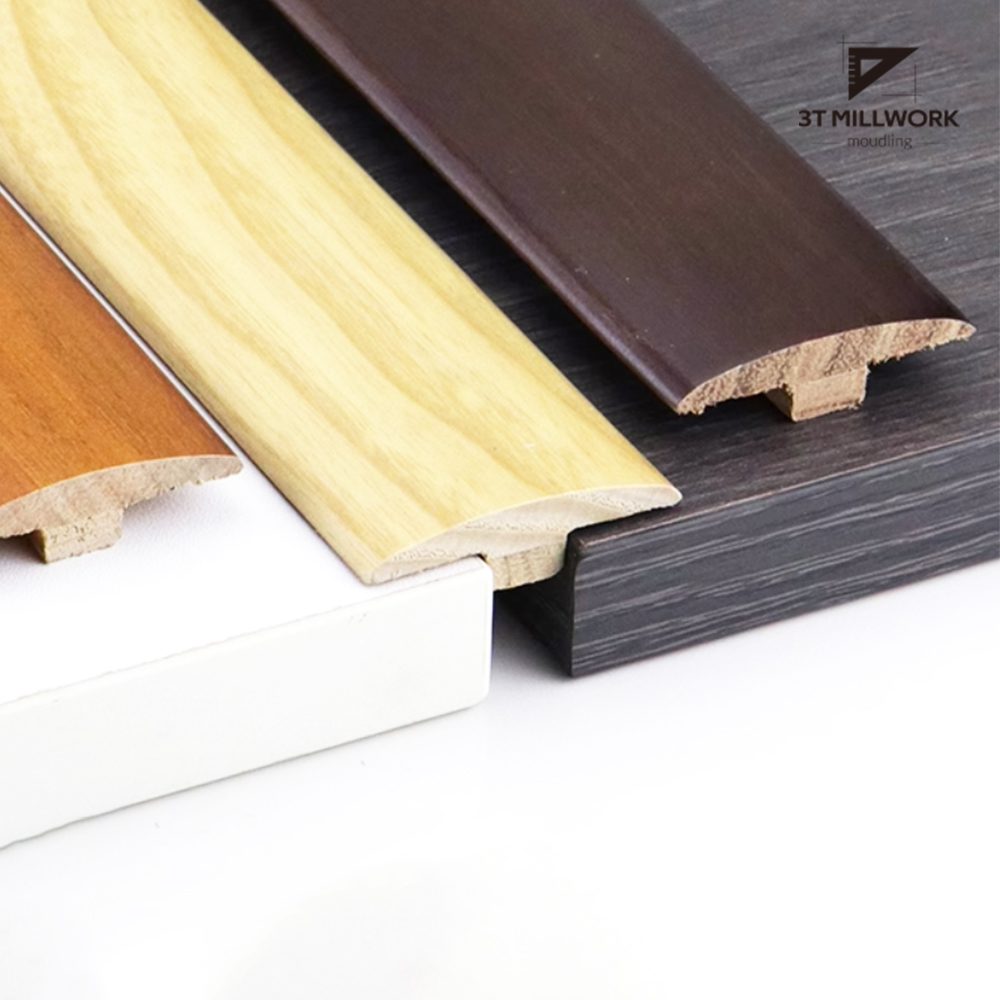

Types of oak t moulding

1

End Cap T-Moulding

End cap unfinished oak t molding, also known as end molding or end cap molding, is used to cover the ends of hardwood flooring, particularly in areas where the flooring meets a vertical surface like a wall, fireplace, or sliding glass door. It provides a finished appearance and helps to protect the edges of the flooring.

2

Overlap T-Moulding

Overlap T-moulding, also known as overlay T-moulding or flush T-moulding, is designed to overlap the edges of two flooring surfaces, creating a seamless transition without the need for a gap between the materials. It is often used in applications where the two surfaces are at the same height, grey oak t molding or any other colors can be done from us.

3

Stair Nose T-Moulding

Stair nose T-moulding, also known as stair nosing, is specifically designed for use on stair treads to provide a finished edge and improve safety by reducing the risk of tripping. It typically features a rounded or bullnose profile that covers the edge of the stair tread, size can be 3 inch reducer molding and 1 inch reducer molding.