Description

What is t mold trim

T molding looks like the letter T. It is mainly used to connect two floors and cover the gap between them. Moreover, after installing T molding, some space is left for the floor, so that the problem of dimensional changes in the floor due to thermal expansion and contraction can be well solved. The size of the molding can be customized according to customer needs. Whether it is 3 4 inch t molding or 3 inch wide t molding, we can produce it. The raw materials and surface effects of molding can also be customized, and we guarantee that we will provide you with products that satisfy you.

Customized products

The size of the molding product needs to match the size of the installation area, so it is very important to provide customized product sizes. Our product sizes are not fixed, whether you need t molding 12mm or 3 4 t moulding, or other product sizes, you You can tell us directly.

Various product categories

As a professional manufacturer of molding products, we can provide a variety of different molding products, such as carpet t molding, baseboard, crown, wall panel, door jamb and other products. And different products can have different styles and different surface finish.

Product quality guaranteed

We provide sufficient guarantee for product quality. If any quality problems occur during the product usage, we will provide you with a satisfactory solution, whether you want to replace a new product or refund the money to you, they are all ok for us

Competitive prices

Our products are produced by our factory and then sold directly to customers without the involvement of traders. Moreover, we insist on giving the best interests to customers, offering the most competitive price to customers to develop a larger market.

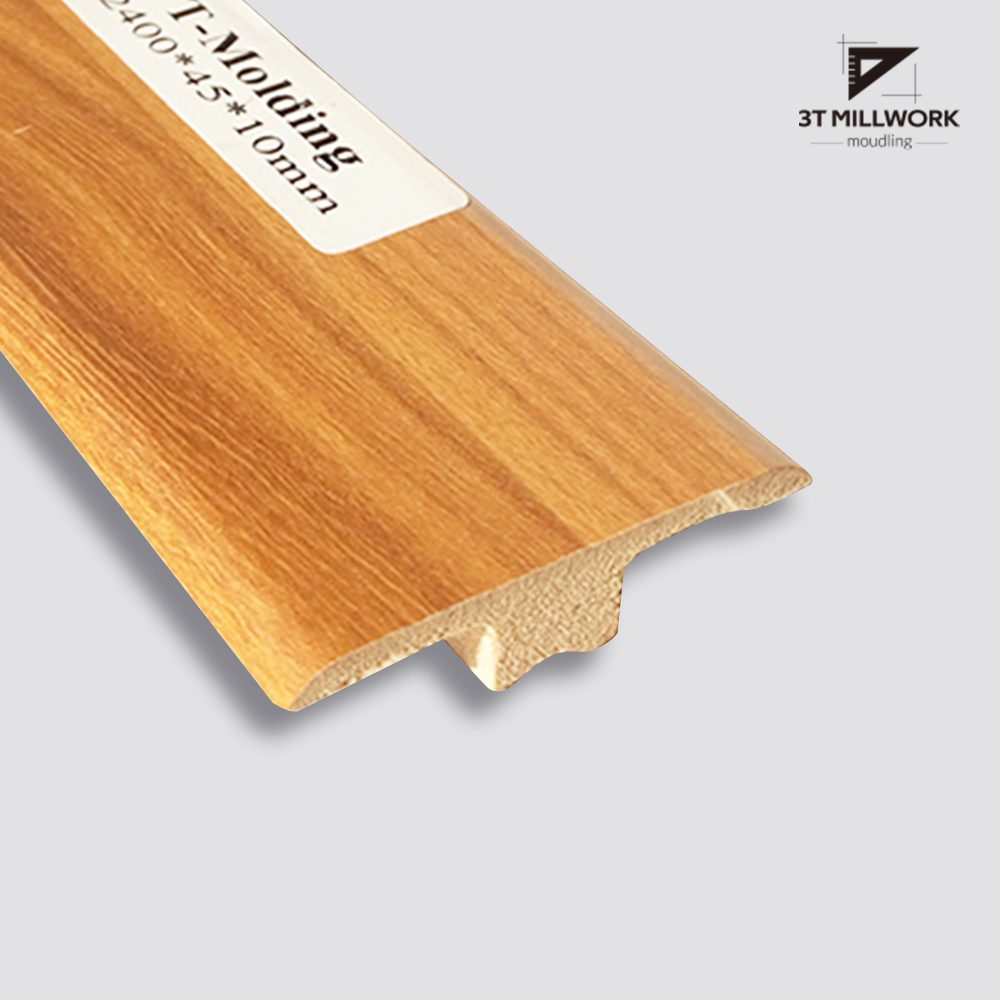

Details of t mold trim

Perfect surface treatment

The surface of T moulding is very clean, and the edge lines are also polished very smooth. T molding does not require additional processing before installation, and can also bring perfect decorative effects after installation.

Accurate product size

The size of the installation location of T molding is relatively small, so the accuracy of the product size must be ensured so that the product can be installed in the designated place. Such as the size of the t molding 1 inch should be 1 inch, no size error.

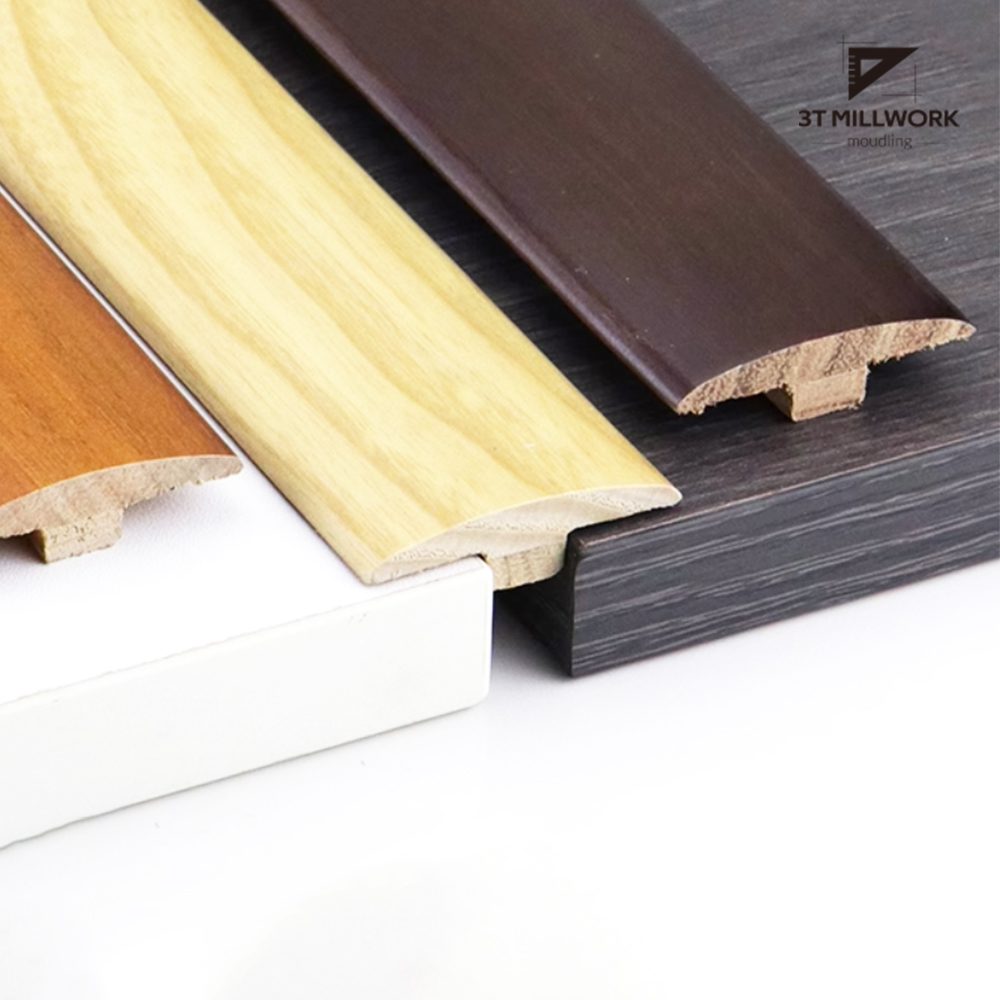

Different surface finishes

T moulding needs to match the different styles and colors of the floor, so a variety of moulding surface finishes are necessary. We have lamination, wood veneer, UV coating, white primed and other effects to choose from.

High quality raw material

Our raw materials include MDF and various wood species, which come from countries and regions where these wood species are abundant and the quality is unanimously recognized. We are all very aware of the importance of raw material quality, so we always choose the best.

Specification of t mold trim

Size

The thickness, width and length of T molding can be made to the size you need, such as the thickness 3 4 t molding, t molding 10mm or 3 inch wide t molding. Of course, the length can be 12ft, 16ft or longer.

Raw material

Both of the MDF and different kinds of wood species can be used to produce the T moulding. They are both very durable, you can choose the right raw material according to your needs.

Surface treatment

We can produce various molding surface effects, the white primed, lamination and wood veneer are all ok for us. If you prefer the t molding carpet to laminate, we have different color for your choice.

Application of t mold trim

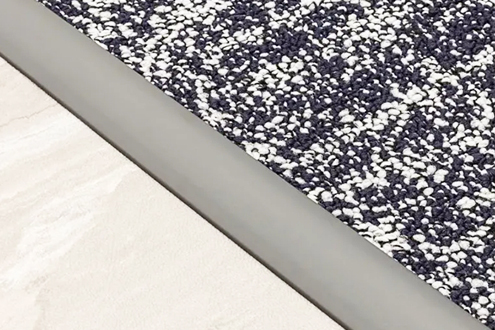

t molding carpet to hardwood

The T moulding can be used to connect carpets and hardwood floors, which can firmly fix them, and the surface effect of the molding can be different, so it can also play a decorative role.

t molding carpet to tile

T moulding can be used to connect carpets and tiles together, so that these two completely different materials can transition together naturally, which provides the possibility for the diversity of your flooring material choices.

carpet t molding

As you know the best wood for door trim need many people in different production processes and many machines, thought now we have more than 135 workers in our factory but you have to prepare more places for many production processes, a large place is necessary for large order.

How to maintain the moulding products

- Keep the environment dry:

Because moulding products are made of MDF and wood, they are not waterproof or moisture-proof, so the storage environment must be kept dry to ensure that the product does not deform or become damp.

- Keep away from fire sources:

Because moulding products are flammable, they must be stored away from fire sources, and staff are not allowed to bring fire into the warehouse. This can protect the safety of the product and ensure the safety of other resources and people.

- Do not stack products too high:

If products are stacked too high, they will cause damage to the products at the bottom and affect the quality of the products. Moreover, stacking products too high is not safe and the products are unstable and easy to slipping.