Description

What is threshold moulding

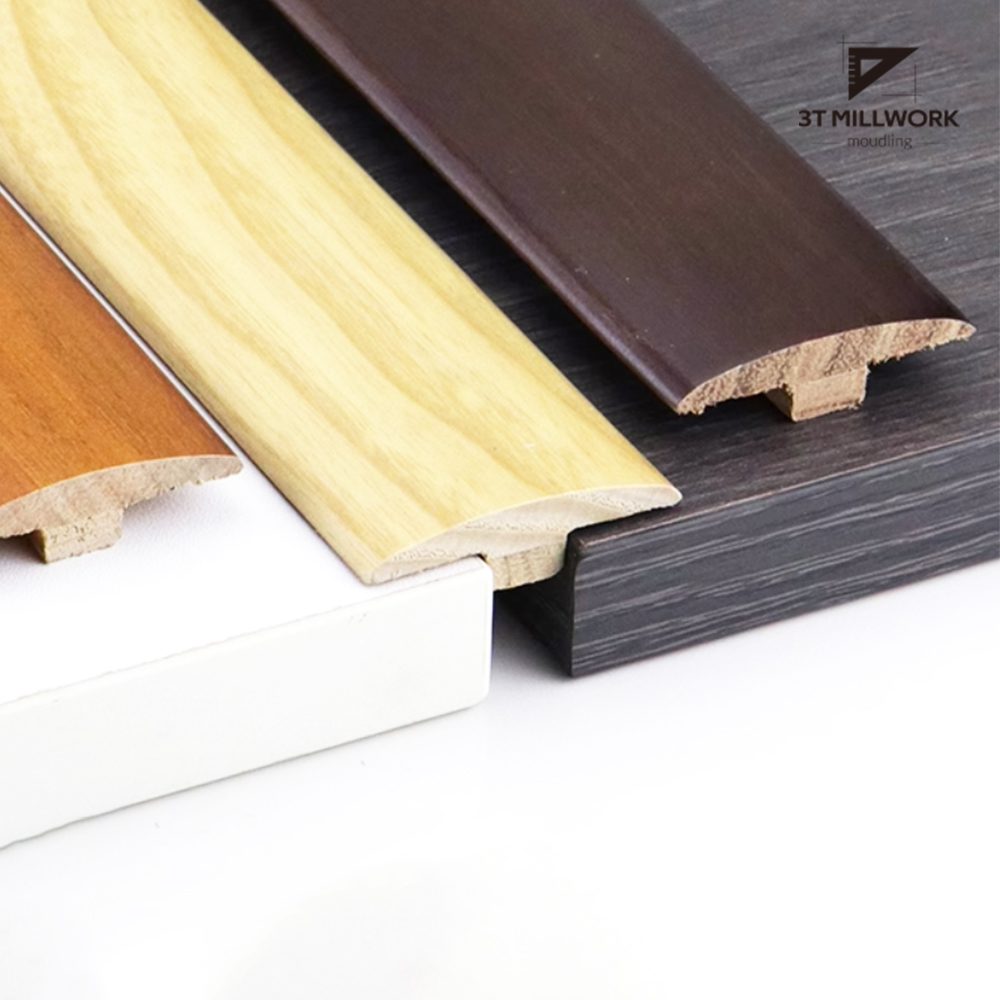

Threshold moulding, also known as a threshold transition strip or simply a threshold, is a type of transition moulding used to cover the gap between two flooring surfaces, typically at doorways or openings between rooms. Its primary function is to create a smooth transition between the different floor heights and to conceal the edges of the flooring materials. Threshold floor moulding serves both practical and aesthetic purposes in flooring installations.

Overall, floor and decor shoe molding plays a crucial role in flooring installations by providing a functional and aesthetic transition between different flooring surfaces. It helps to create a cohesive and visually appealing look while ensuring safety and durability in high-traffic areas.

Maintenance

Shoe molding floor and decor requires minimal maintenance to preserve its appearance and functionality. Regular cleaning with a damp cloth and occasional polishing can help maintain its natural beauty and protect it from scratches or stains.

Long-Term Value

Investing in hardwood floor shoe molding adds long-term value to the flooring installation. Its durability, aesthetic appeal, and compatibility with various flooring materials contribute to the overall value and appeal of the space.

Smooth surface

Due to the good fiber of the hardwood like cedar shoe molding, you can get a super product if you use solid wood material, smooth surface allow you can do the last coating easily.

Strength of our company

Quality Control

Implementing rigorous quality control measures throughout the manufacturing process ensures that floor edge moulding meet quality standards and performance requirements. This helps to build trust and confidence among customers in the company’s products.

Distribution Network

A strong distribution network enables the company to efficiently distribute shoe molding uneven floor products to customers across various regions. This includes partnerships with retailers, distributors, and contractors to reach a wide customer base.

Innovation and Technology

Staying up-to-date with the latest manufacturing technologies and innovations allows the company to improve efficiency, enhance attaching shoe molding quality, and introduce new features or designs to meet changing customer demands.

Why Choose us

Expertise and Specialization

Door floor trim factories are dedicated to the production of moulding products. They have specialized knowledge, experience, and equipment specifically tailored for manufacturing mouldings. This expertise ensures that the commercial floor molding produced meet industry standards and customer expectations.

Quality Control

Factories typically have stringent quality control measures in place to ensure the consistency and quality of their end cap floor molding. They implement rigorous testing and inspection procedures throughout the manufacturing process to identify and rectify any defects or discrepancies, thereby ensuring that the floor end molding meet predefined quality standards.

Advanced Technology and Equipment

Floor to door trim factories invest in advanced technology and equipment to streamline the manufacturing process and improve efficiency. This includes precision machinery for cutting, shaping, and finishing mouldings, resulting in high-quality t molding doorway with precise dimensions and finishes.

Customization and Flexibility

Many moulding factories offer customization options to meet specific customer requirements. They can produce mouldings in different sizes, profiles, materials, and finishes, providing customers with a wide range of options to suit their unique needs and preferences.

Specification of threshold moulding

Transportation

You can choose sea shipping with FOB or CFR from us, we supply you methods with DDU and DDP with good price, you can share your correct information to get our price list for entry door floor molding products.

Surface finishing

Besides primed on the surface of end molding floor, you can choose lamination, veneer, paint treatment moulding from us, some of them are semi finished and some of them are finished threshold molding.

Dimension and tolerance

Dimension are more correct for producing, the tolerance is little like +/- 0.05 mm for the thickness and 0.3mm for the length, you do not need to worry about anything of the door threshold floor trim size.

Quality control

We do have more strict quality control system and more professional quality control team in our factory, you can reply on us if you worry about the quality of the threshold floor molding.

The benifits of our threshold moulding

Smooth Transition

One of the primary benefits of door edging floor trim is its ability to create a smooth transition between two different flooring surfaces. Whether transitioning from one room to another or from one type of flooring material to another, such as tile to hardwood, floor door molding ensures a seamless flow, reducing tripping hazards and providing a polished appearance.

Conceals Gaps

Door trim for floor covers the gap between two flooring surfaces, effectively concealing any irregularities or gaps that may exist between them. This helps to prevent debris, dust, and moisture from accumulating in the gap, maintaining a cleaner and more hygienic environment.

Protects Edges

By covering the edges of the flooring materials, floor molding for doorways helps to protect them from damage, such as chipping, cracking, or splintering. This is particularly important in high-traffic areas or areas prone to wear and tear, ensuring the longevity and durability of the flooring installation.

Enhances Safety

T molding in doorway contributes to safety by minimizing the risk of tripping or stumbling over uneven transitions between flooring surfaces. This is especially beneficial in homes with young children, elderly individuals, or individuals with mobility issues, as it helps to create a safer living environment.

Application of threshold moulding